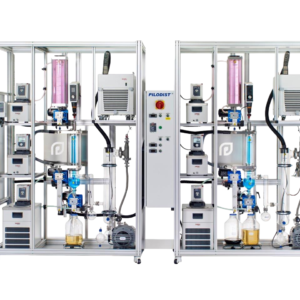

Fully automatic and continuous solvent recovery & recycling system for winzerized botanical extracts with the following operation steps:

- Removal of ethanol from herbal extracts

- Decarboxylation (optional)

- Ethanol conditioning (water removal) for recycling use

Key features: - Stainless steel evaporator (AISI 316)

- Fully automatic unattended operation

- Vacuum conditions to prevent thermal degradation

- Integrated hot-steam heat exchanger for gentle heat transfer with maximized surface

- PLC-controlled program cycle with remote access and sophisticated safety system

- Large inspection opening for easy access

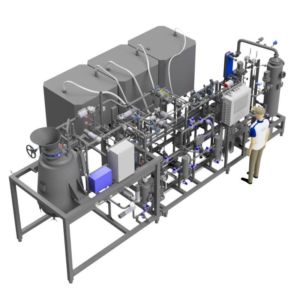

TECHNICAL DATA:

| Evaporation capability | 30-50 l/h |

| Temperature range | 100°C – 160°C |

| Operating Pressure | ATM – 150 mbar abs. |

| Electrical load | 9 kW |

| Required cooling water | 15°C – 25°C (suitable chiller optional availible) |

| Dimension | 1100 mm x 1600 mm x 1995 mm |

| Net weight | 360 kg |

The system is designed to fulfill the CE-conformity for the operation with flammable liquids (ATEX design review for internal atmosphere).

Customers from US and Canada please contact our exclusive channel partner PRESCOTT LOGIC TECHNOLOGIES

Please also check our general PILODIST website to find out more about us and our complete scope of laboratory and distillation equipment.

Customers from US and Canada please contact our exclusive channel partner PRESCOTT LOGIC TECHNOLOGIES

Please also check our general PILODIST website to find out more about us and our complete scope of laboratory and distillation equipment.