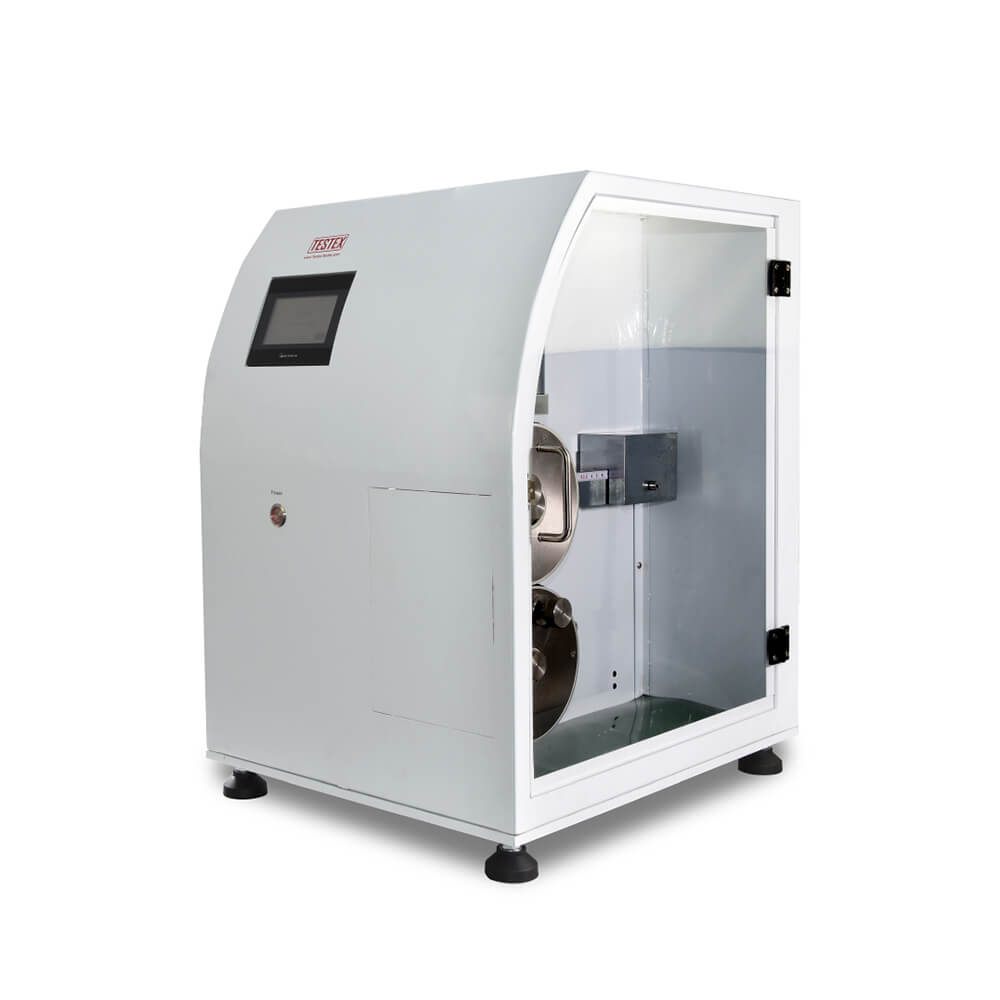

The seam Fatigue Tester is applied to determine the strength of upholstery seam constructions which are covered by a standard foam composite cushion by imposing a cyclic, impact, and penetrating load. Dynamic Seam Fatigue Tester complies with ASTM D4033, etc. And TESTEX is one of the best Dynamic Seam Fatigue Tester manufacturers. If you are interested in it, welcome to visit our website.

Description

Application

Dynamic Seam Fatigue Tester is specially designed to test the strength of upholstery seam constructions which are covered by standard foam composite cushions by imposing a cyclic, impact, and penetrating load. Dynamic Seam Fatigue Tester enjoys a wide application in many industries, such as automobiles, garments, and fabrics.

A rubber-faced wheel of 127mm (5”) diameter impacts the fabric from a height of 150mm (6”) with a mass of 3.75 kg (8.25lbs), 25 times per minute for 7000 cycles. Besides, the Dynamic Seam Fatigue Tester has 3 work positions and 6 positions complying with the requirement. Moreover, it can make 23 or 27 cycles in one minute. Thus, it can be in operation at a relatively high speed.

Specifications

- Testing frequency: 25+/-2 cycle/min

- Testing cycles: 7,000

- Impacting mass: 3.75 kg

- Foam composite: 228.5 x 280 x 178 mm

- Dimensions of sewn specimen: 360 x 255 mm

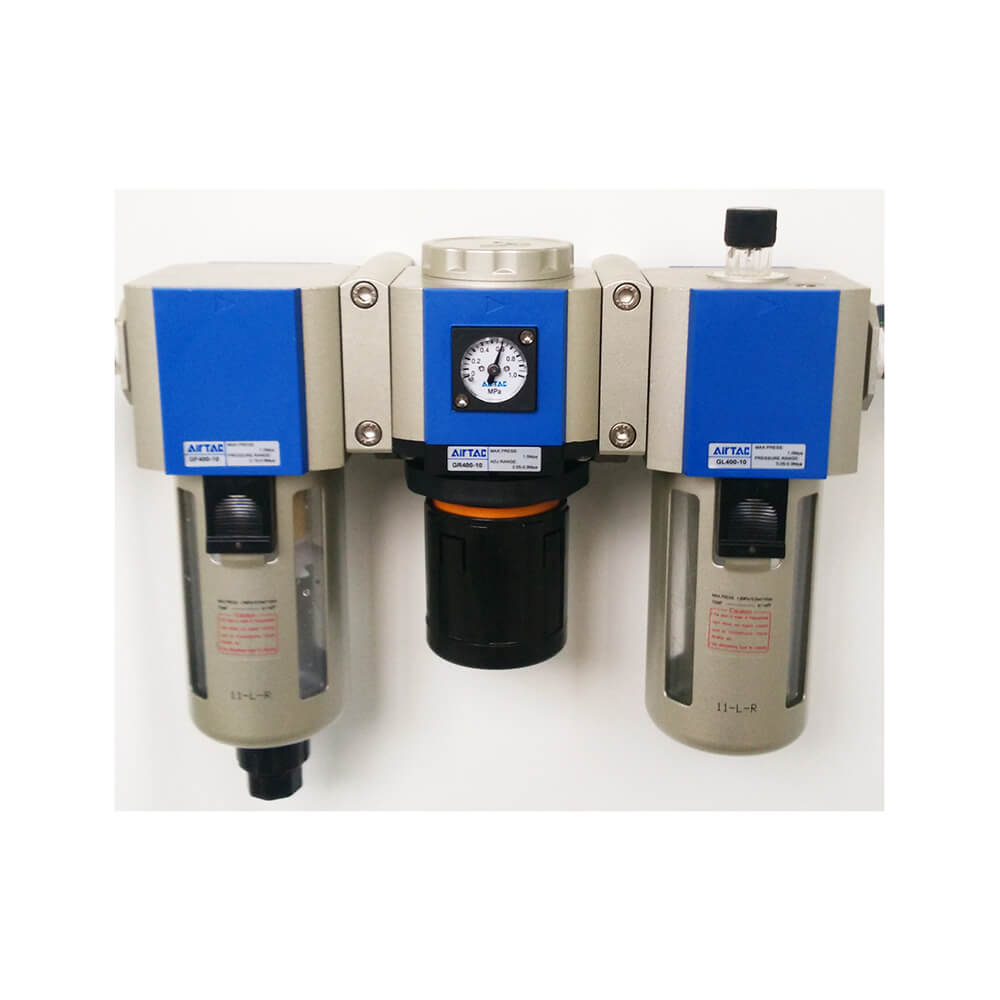

- Driving mode: Pneumatic

Weight

| 350 kg |

Power

| 220/110 V | 50/60 Hz |

Dimensions

| Length: 1600 mm | Width: 860 mm | Height: 1450 mm |

Standards

| ASTM D4033 |

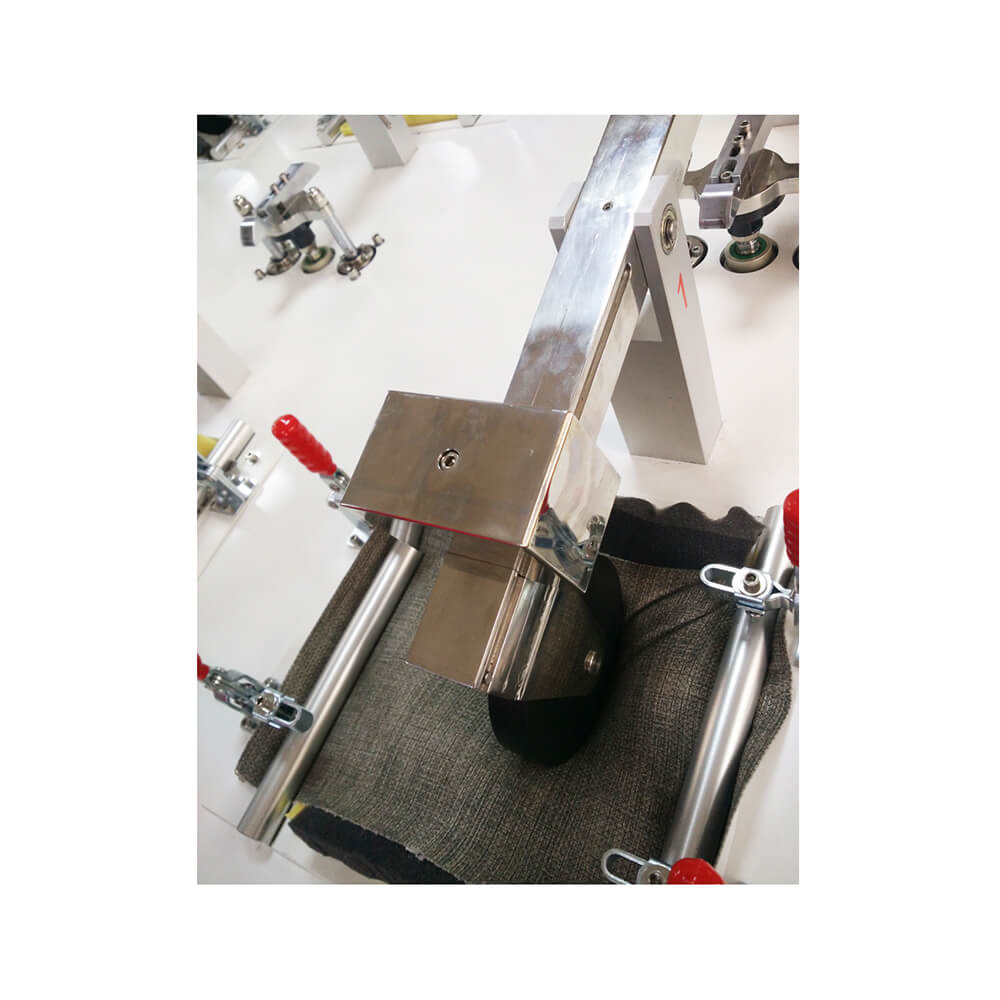

Test Principle

The dynamic seam fatigue test machine is suitable for testing the dynamic fatigue resistance of the seams of sofa fabrics. Fix a sample with a seam joint to a specimen seat containing an elastic foam pad, clamped on both sides, and use a free rotating rubber wheel of a certain weight, to impact the surface of the specimen continuously from a certain height, until the specified number of times to check the damage degree of the sample.

Why do We Need a Dynamic Seam Fatigue Test?

Dynamic seam fatigue testing machine is designed to test the seam fatigue degree of automobile seats, domestic sofas, and other surface materials. The surface materials of sofa seats, such as leather, synthetic leather, fabric, and so on, are stitching structures. And the seam strength of the connection and fatigue resistance for these materials put a direct effect on the service life of the seat. Apart from that, we can also predict the life effectively of the seat. In addition, we can provide a reference value for improving the service life of the sofa seat by testing the strength and life of the material seam.

It is simple to operate the dynamic seam fatigue tester produced by our company. Besides, the TF152 calls for less daily maintenance. It supports six working stations to test at the same time, and the number of stations can be customized according to customer requirements. The instrument adopts a caster wheel to support, making the movement flexible, adjustment convenient, and noise low when testing. Please contact us if you want to know the price of the dynamic seam fatigue tester.

Welcome to TESTEX – a professional textile testing instrument supplier. Dynamic Seam Fatigue Tester is on sale, contact us to get a detailed price quote.