The horizontal Flammability Tester is called the horizontal method of flame retardant performance tester, used for all kinds of textile fabrics horizontal direction burning performance determination, and the flame spread rate to express. Used for simulation technology to assess the risk of fire, and the product’s surrounding fire to ensure that it does not cause the spread of combustion. Horizontal Flammability Tester complies with ISO 3795, ISO 17074, DIN 75200, etc.

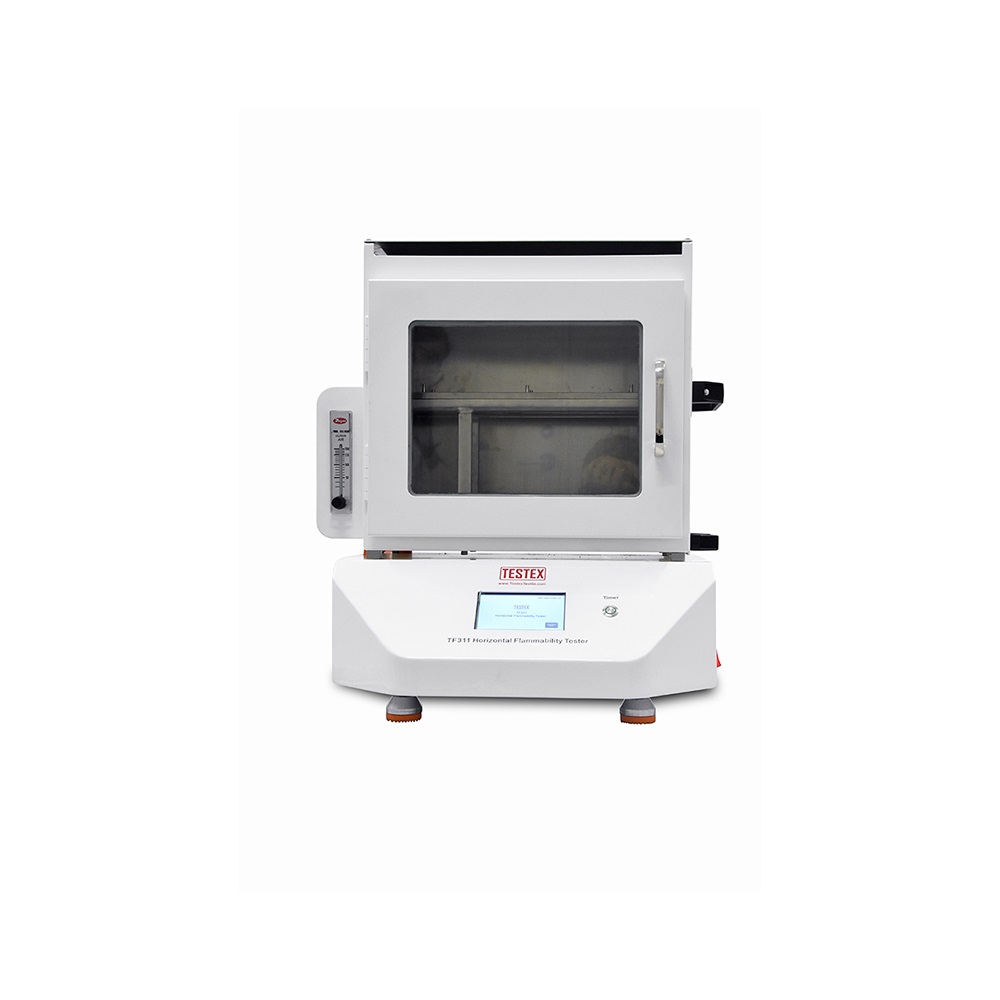

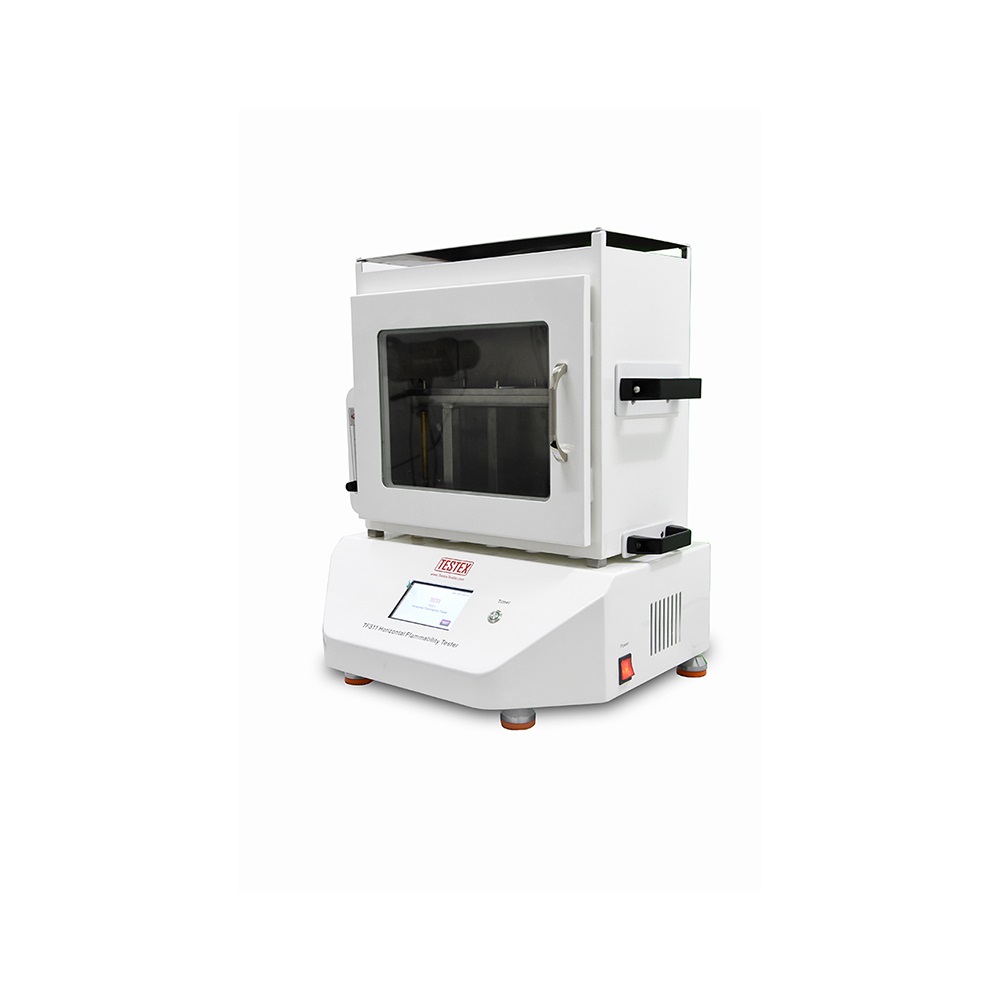

This Flammability Tester has a small size, so it can be placed on the desktop, you can do the flame test with many kinds of flammability test standards. The flammability testing method is simple you can master it quickly. This flammability test equipment also has an ultra-large observation window, you can more clearly see the fabric burning situation.

Description

Application of Horizontal Flammability Tester TF311

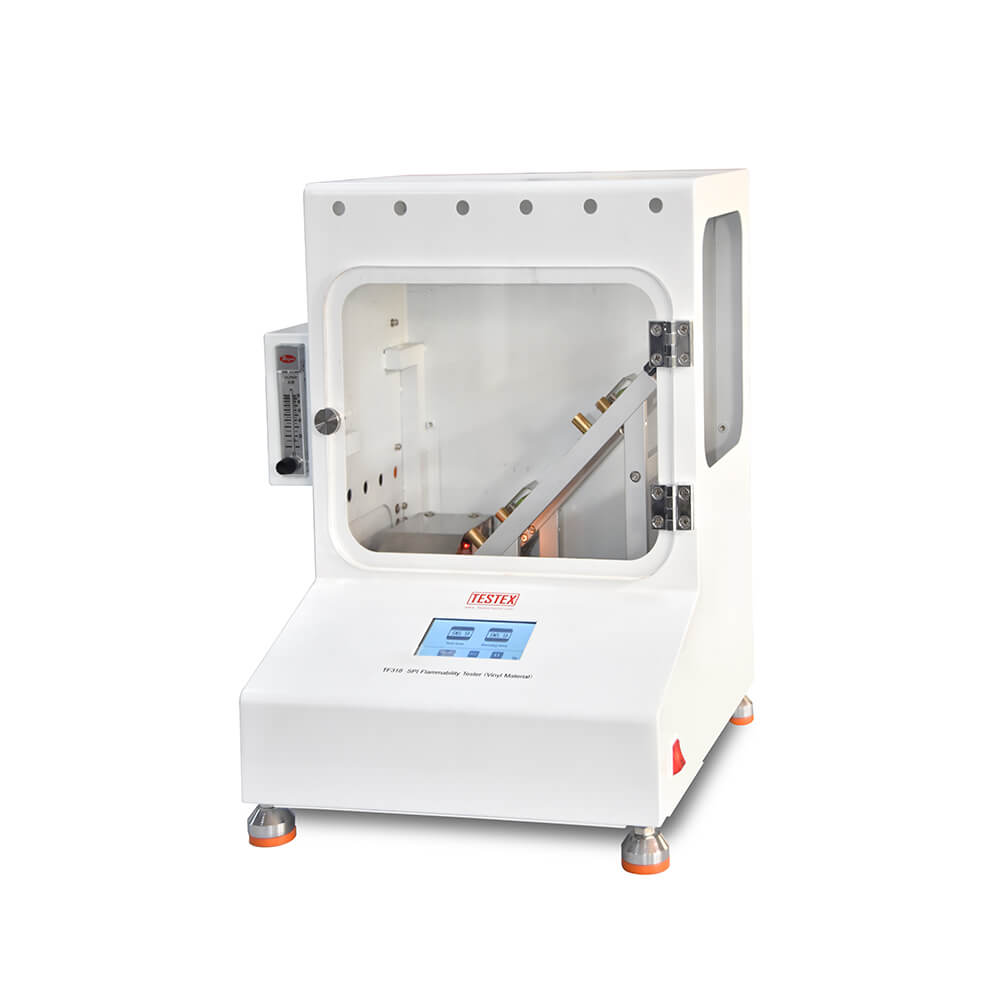

The Horizontal Flammability Tester is suitable for testing the flame retardant properties of leather interior materials, polymer materials, textiles, etc. Such as used in all kinds of automobiles, including seat cushions, seat belts, roof linings, armrests, decorative panels, headrests, floor coverings, sun visors, curtains, and other interior parts. Thus, it provides the data basis for new material research and development, product quality acceptance, etc.

In addition to TF311, we also have a series of other flammability testers that you can click to learn more about.

Features of Horizontal Flammability Tester TF311

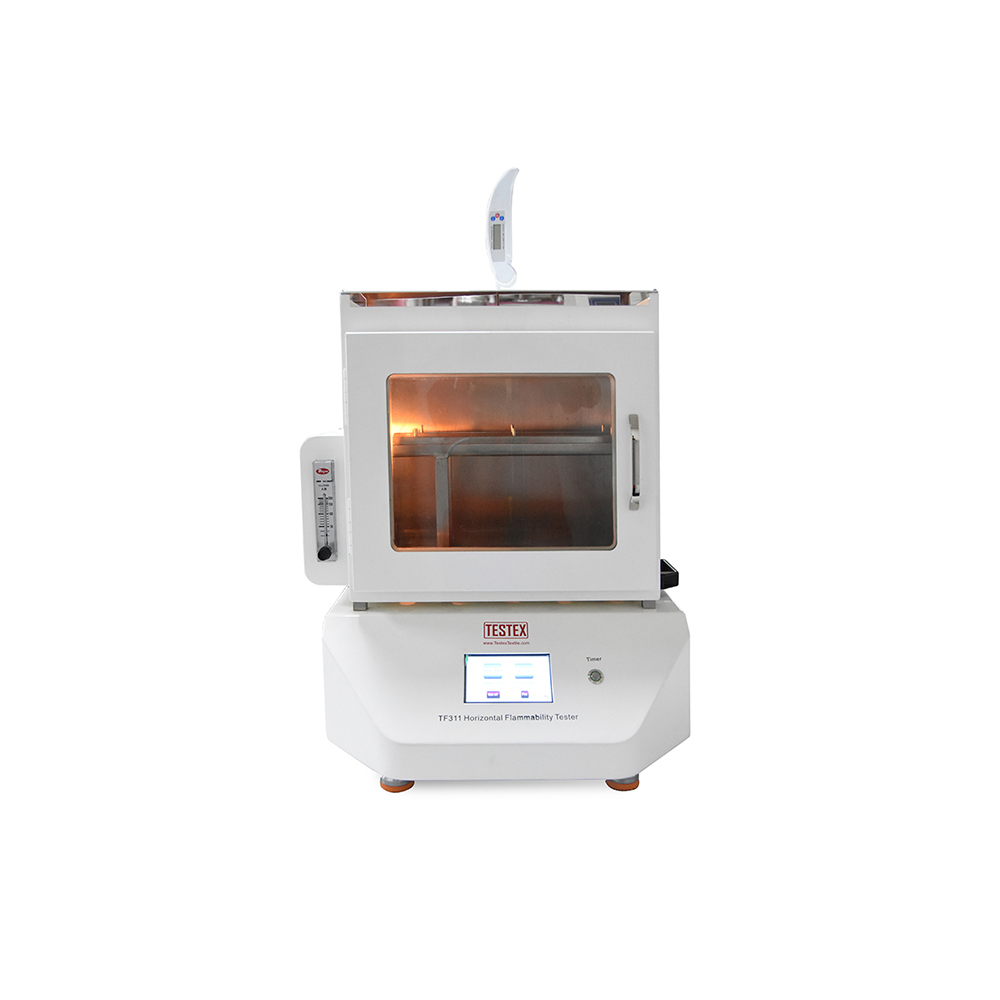

Safety settings: the flammability tester box shell is a steel structure and encloses the testing process. Through the transparent observation window, you can clearly observe the whole combustion process.

Accurate: the test data is consistent with internationally renowned third-party laboratories.

Very simple operation: gas and fire buttons, an LCD program, real-time display of ignition time and combustion time.

The high degree of automation: automatic recording of test time, automatic display of results and automatic timing once the test starts.

Reasonable design: Equipment with its own fan, test combustion fumes safely discharged.

The flammability testing machine is beautiful in appearance, easy to use, and reliable in performance.

Specifications of Horizontal Flammability Tester TF311

- Fire nozzle DIA: 9.5mm

- Fire height 38mm+/-2

- Sample clamp 360 x 100mm / Interior dimension 330x50mm

- The sample below 25mm pitch between metal wire is 25mm

- Marked line Starting point 38mm / Endpoint 292mm from the Ignition point

- Nozzle to Sample 19mm

Standard Accessories of Horizontal Flammability Tester TF311

- Metal combs

- Punch

- Sampling plate

- Bunsen burner (φ9.5mm)

Weight

| 46 kg |

Power

| 220/110 V | 50/60 Hz | 3 A |

Dimensions

| Length: 485 mm | Width: 360 mm | Height: 570 mm |

Standards

| ISO 3795 | GB/T 8410 | DIN 75200 | ISO 17074 |

| ECE R118 Appendix 6 |

Optional Standards

| FMVSS 302 (Ф 10mm Flame nozzle) |

|---|

Why Choose TESTEX Horizontal Flammability Tester TF311

Strictly meet standards

All data for TF311 meet the standard parameters.

Consistency with international third-party laboratories

The test data are comparable to the test results obtained by well-known international third-party laboratories.

High repeatability

With the same set of samples, the same machine, after multiple tests, the results are consistent.

High reproducibility

With the same set of samples, and different machines of the same model, after multiple tests, the results are consistent.

Longer service life

TESTEX makes prototypes and then subjects them to rigorous reliability testing in a variety of environments to ensure achieve the expected service life.

User-friendly transparent warranty policy

Textile testing machines, 14 months free warranty (12 months normal warranty time + 2 months shipping time). Besides, all spare parts, have 3 months free warranty.

We provide full life-cycle support for Horizontal Flammability Tester TF311. So feel free to contact our service team with any questions you may have.

Precautions for Operating the Horizontal Flammability Tester TF311

- Place the test equipment in a well-ventilated environment to avoid the toxic fumes generated during the test to affect the health of the operator.

- During the test, this equipment should be grounded to avoid electrostatic reactions.

- When connecting the air source, attention should be paid to the air pipe for air leakage.

- After the test, clear the combustion residue in time to keep the equipment clean.

- Spray anti-rust oil on the surface of this equipment regularly to prevent rust and corrosion after a long time.

- Regularly inject lubricant into the transmission parts of this equipment to ensure that each test can be carried out smoothly.

Welcome to TESTEX – a professional textile testing instrument supplier – Horizontal Flammability Tester is on sale, contact us to get a detailed price quote.