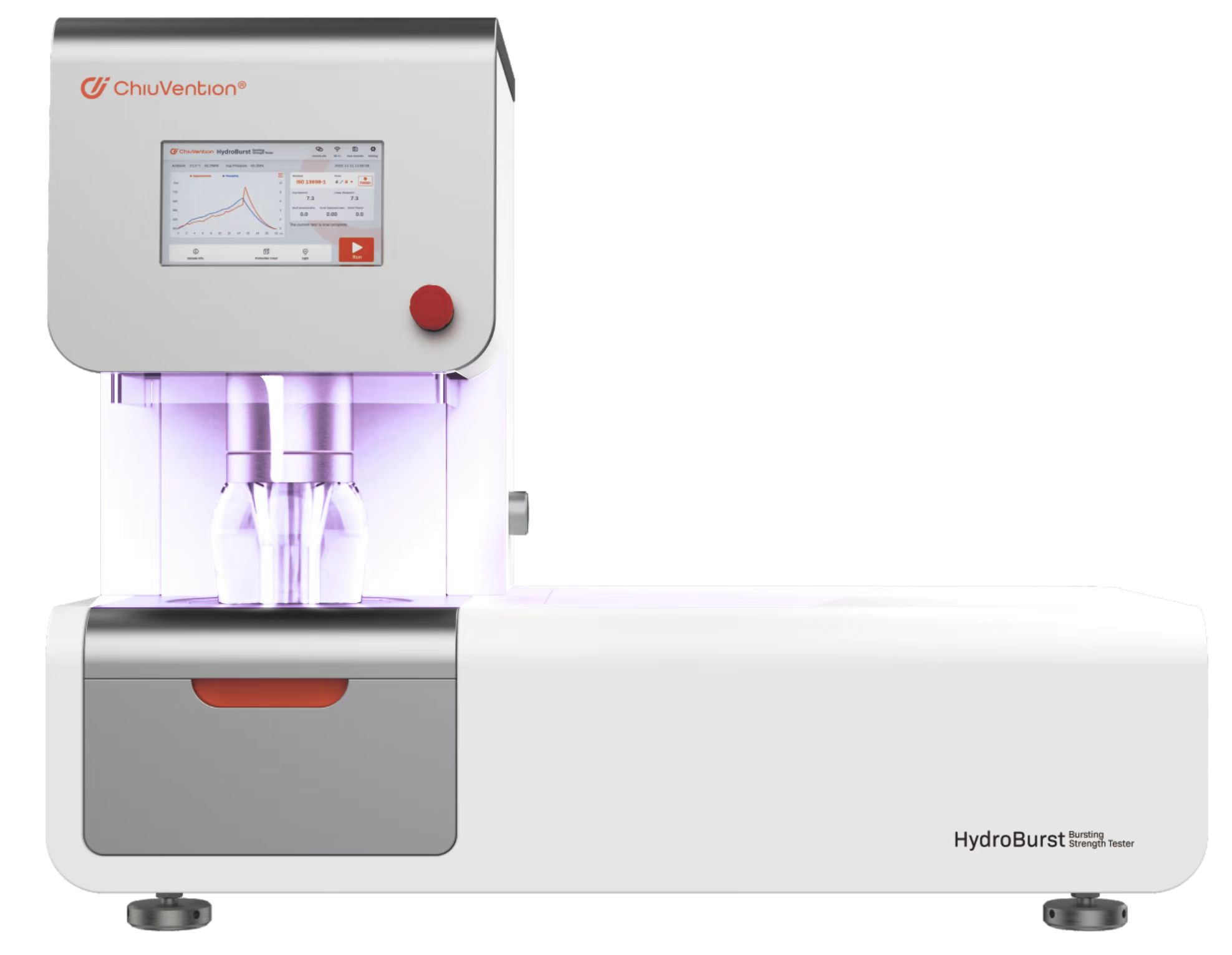

The HydroBurst Burst Strength Tester utilizes hydraulic bursting (diaphragm method) to determine the burst strength and expansion of knitted fabric, woven fabric, non-woven fabric, laminated fabric, elastic woven fabric, paper, and other materials when subjected to stress in both warp and weft directions, as well as in all other directions, to get the material’s burst strength.

It is also called a BS tester or Mullen Burst Tester. The HydroBurst Burst Strength Tester is widely used for fabric or paper burst tests.TESTEX is a professional Burst Strength Tester manufacturer.

We provide you with hydraulic bursting strength testers but also pneumatic bursting strength testers. Our Digital Bursting Strength Tester complies with many bursting strength test standards, such as GB∕T7742.1-2005, ISO13938-1-2019, ASTM D3786/D3786M-18, etc.

Description

Features of Bursting Strength Tester Machine

Smart instrument

The Burst Tester can connect to a mobile phone, enabling remote control and monitoring of the testing status. You can access the burst strength test results and print them as needed. The bursting tester also provides reminders for equipment warnings. Furthermore, this BS tester allows for one-click sharing of the testing status.

Smooth operation, precise, and durable.

The Burst Tester features a hydraulic system with complete servo control and a precise screw drive. These attributes ensure smooth, durable, and quiet operation, making it a high-quality burst strength tester.

High-precision testing

The BS Tester is designed to measure pressure and features a high-precision pressure sensor. This bursting strength machine’s sensor offers an accuracy of 0.2%, which means the burst test error is 0.2% of the maximum range.

Longer service life of sensors.

The Mullen Burst Tester features Panasonic laser displacement sensors without rods, making it easy to replace testing cups. This design protects the sensors and minimizes the risk of damage compared to traditional rod-type sensors.

Automatic testing improves efficiency.

During the burst strength test, the protective cover automatically lowers to press the BS tester cup for evaluation. Once the test is complete, the machine automatically raises the testing cup, and the protective cover ascends as well. This entire burst test process is automated, requiring no manual operation, which enhances work efficiency and minimizes risks.

A smart identification system for testing cups.

When replacing the BS testing cup, the system can recognize the current cup model and adjust the testing settings accordingly. This enhancement significantly boosts work efficiency. Additionally, the HydroBurst BS Tester features a steel plate shell with an electrostatic spray finish, giving it an appealing appearance. Internally, this fabric bursting strength tester is constructed mainly from high-quality, lightweight aluminum, which substantially reduces the overall weight of the machine.

Application of Bursting Strength Tester

Bursting Strength Tester is applicable for truck covers, trampoline fabrics, swimming pool covers, compactor curtains, agricultural bagging applications, etc. We should test the above textiles using a burst tester to ensure the burst strength meets the specified requirements.

The HydroBurst Digital Bursting Strength Tester is a hydraulic type, that provides a digital pressure value with a peak hold facility and renewable rubber diaphragms. In addition, an automatic clamping device with a clear acrylic bell and an LED lamp is equipped for easy observation. It is easy for users to burst the strength of the fabric and the burst strength of paper.

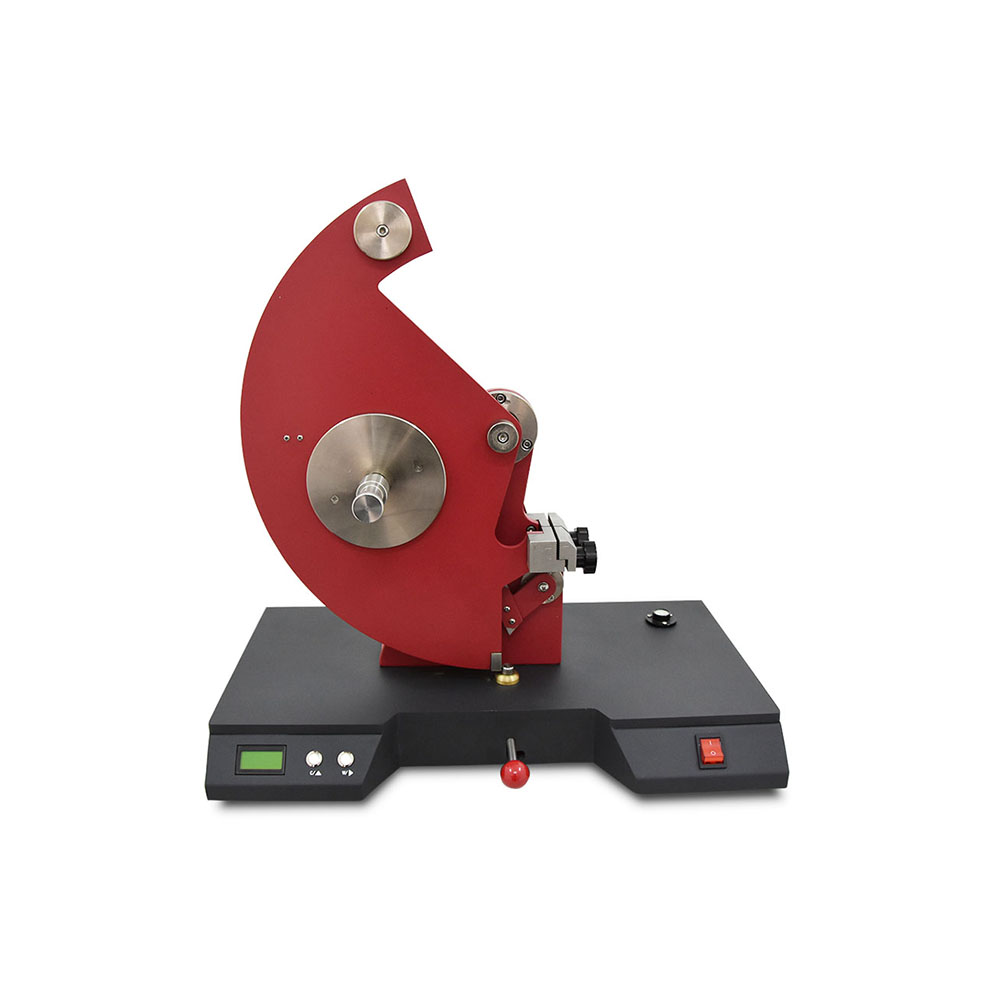

Note: This bursting strength machine measures hydraulic bursting strength using the diaphragm method. For pneumatic bursting strength testing, use our Fabric Pneumatic Bursting Tester TF142C.

Customer Feedback of Bursting Strength Testing Machine

“We have been purchasing textile test instruments from top brands, and we found ChiuVention is a very trustworthy brand, with the same quality as the top brands and at a reasonable price; The HydroBurst has been running very stably since we have been using it.” by Bernard / A textile science and technology research institute in France

“ChiuVention has an agent in Indonesia, which is more convenient for after-sales service for us. And the most important point is this HydroBurst meets the requirements in all aspects and cost-effective.” by Amalia / Home textile dyeing and finishing company in Indonesia

Specifications of Bursting Strength Tester

| Model | No. 1. CV.142.01 CV142 HydroBurst Bursting Strength Tester |

| Testing mode | fixed-speed bursting, fixed-pressure bursting, fixed-expansion bursting, and fixed-time bursting. |

| Measurement range | 0-10 MPa ±1% ( with test cup ≤ 10cm²)

0-3 MPa ±1% ( with test cup = 50cm² ) 0-1 MPa ±1% ( with test cup = 100cm²) |

| Testing rate | 50-500 ml/min. |

| Hydraulic medium | 7.HY.004 glycerin 500ml/1 pc |

| Power | 220V 5A / 110V 10A 50/60Hz |

| Weight | 130kg |

| Dimension | 830*500*660mm (L*W*H) |

| Test cup mode、Fixture mode and related dimensions | |

| Test Cup 1(Standard) Lower fixture base 1(Standard) |

2.Z.CV.142.01 7.3cm²(Dia.30.5mm±0.2mm) 2.Z.CV.142.11 7.3cm²(Dia.30.5mm±0.2mm) |

| Test Cup 2 (Optional) Lower fixture base 2(Optional) |

2.Z.CV.142.02 7.55cm² (Dia. 31mm±0.2mm) 2.Z.CV.142.12 7.55cm² (Dia. 31mm±0.2mm) |

| Test Cup 4 (Optional) Lower fixture base 4(Optional) |

2.Z.CV.142.04 10cm² (Dia. 35.7mm±0.2mm) 2.Z.CV.142.14 10cm² (Dia. 35.7mm±0.2mm) |

| Test Cup 5 (Optional) Lower fixture base 5(Optional) |

2.Z.CV.142.05 50cm² (Dia. 79.8mm±0.2mm) 2.Z.CV.142.15 50cm² (Dia. 79.8mm±0.2mm) |

| Test Cup 6(Optional) Lower fixture base 6(Optional) |

2.Z.CV.142.06 100cm² (Dia. 113 mm±0.2mm) 2.Z.CV.142.16 100cm² (Dia. 113 mm±0.2mm) |

| Test diaphragm (optional) | 4.M.020 Dia. 148 mm * 1.6 mm (10pcs/box) |

| Maximum expansion height | 65 mm ±1 mm(with a test cup of 50cm² also can be used for 70mm ± 1mm). |

| Operating environment | temperature: 20°C ±5°C, humidity: 50%~70%. |

| Installation conditions | air supply pressure of 5~8 bar (Note: please ensure that the air is clean and dry). |

Standards of HydroBurst Burst Strength Tester

FZ/T 01030-2016 Method B

GB∕T 7742.1-2005

ISO 13938-1-2019

ASTM D3786/D3786M-18(2023)

EN 12332-2-2002

| Standard / Specification | FZ/T01030-2016 Method B | GB∕T7742.1-2005 | ISO13938-1-2019 | ASTMD3786/3786M-18(2023) | EN 12332-2-2002 | |

| Test Fixture | 7.3cm2 (φ30.5mm) | √ | √ | √ | √ | – |

| 7.55cm2 (φ31±0.75mm) | – | – | – | √ | – | |

| 10cm2 (φ35.7±0.5mm) | – | √ | √ | – | √ | |

| 50cm2 (φ79.8mm) | – | √ | √ | – | – | |

| 100cm2 (φ113±1mm) | – | √ | √ | – | √ | |

Test Principle of Bursting Strength Tester

Our Fabric Bursting Strength Tester operates by securely fixing the fabric specimen onto a deformable film. The Digital Bursting Strength Tester then applies hydraulic pressure to the film, causing the fabric to expand until it bursts. The Bursting Strength Apparatus calculates the fabric’s expansion strength by measuring the difference between the total pressure required to burst the sample and the pressure needed solely to deform the film. This reliable and precise method ensures accurate assessment of fabric durability and expansion strength, making our tester ideal for professional textile testing applications.

Significance of the Bursting Strength Test of Fabric

Tensile strength testing is not as relevant for certain fabrics, such as knitted materials and lace, where bursting strength testing can be more appropriate. When a fabric fails, it typically experiences pressure in the warp, weft, and diagonal directions. For instance, some knitted fabrics, like weft knitted types, stretch in a linear direction while contracting transversely, with these two directions influencing one another. In tensile strength testing, it is necessary to evaluate the warp, weft, and diagonal directions individually, whereas bursting strength testing provides a comprehensive assessment of the fabric’s overall strength in a single evaluation.

Choose the right bursting strength tester in 5 steps:

Define Your Needs

Determine your testing requirements and application scenarios. Identify the material type, testing frequency, and mechanical properties to measure.

Select the Right Tester

For high-accuracy needs, opt for a hydraulic bursting strength tester—ideal for lab or production line use, offering stability and precision. For quick and on-site tests, a Pneumatic Bursting Tester is more affordable and user-friendly.

Evaluate Operation & Maintenance

Hydraulic systems require skilled operators but provide robust performance, while pneumatic systems are simpler and better for non-experts. Choose equipment from a reliable bursting strength tester manufacturer or supplier with low maintenance needs.

Consider Automation & Data Processing

Boost efficiency with testers equipped with automation and data analysis capabilities. Modern instruments provide real-time results and detailed reports.

Set a Budget

Hydraulic testers are pricier but offer unmatched accuracy and stability. Pneumatic Bursting Testers are cost-effective for budget-conscious users.

Choose a trusted bursting strength tester supplier for durable and efficient equipment tailored to your needs.

Welcome to TESTEX – a professional bursting strength tester manufacturer -The Burst Testing Machine is on sale, contact us for a bursting strength tester price. We provide you with a reasonable hydraulic bursting strength tester. Besides, you can get knowledge of the burst strength of the fabric, paper, carton, etc. burst strength tester, and bursting strength tester pdf by visiting our blog.