Description

Features of Crockmeter TF411

precision slide rail

2. Both wet and dry rubbing testing can be performed.

3. Advantageous test sets

An enormous-sized specimen

4. Meet strict standards

Parts

stable performance

easy to change

Handleportable

prolonging the service life

6. The load weight can be selected.

Regularly, the reciprocating load arm is weighted to provide a constant 9N load on the sample at all times, and TESTEX can design other weights if you need them.

TF411 is equipped with a mechanical counter that keeps track of completed cycles.

Specifications of Crockmeter TF411

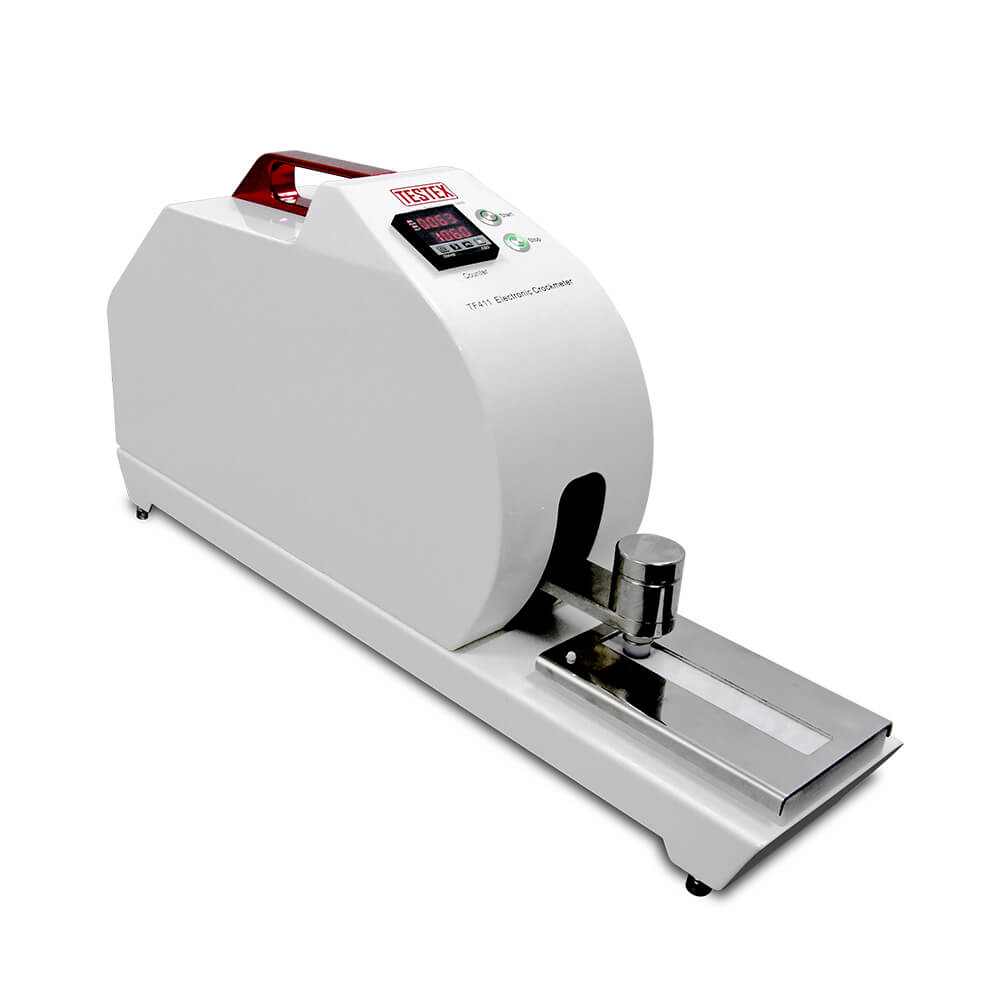

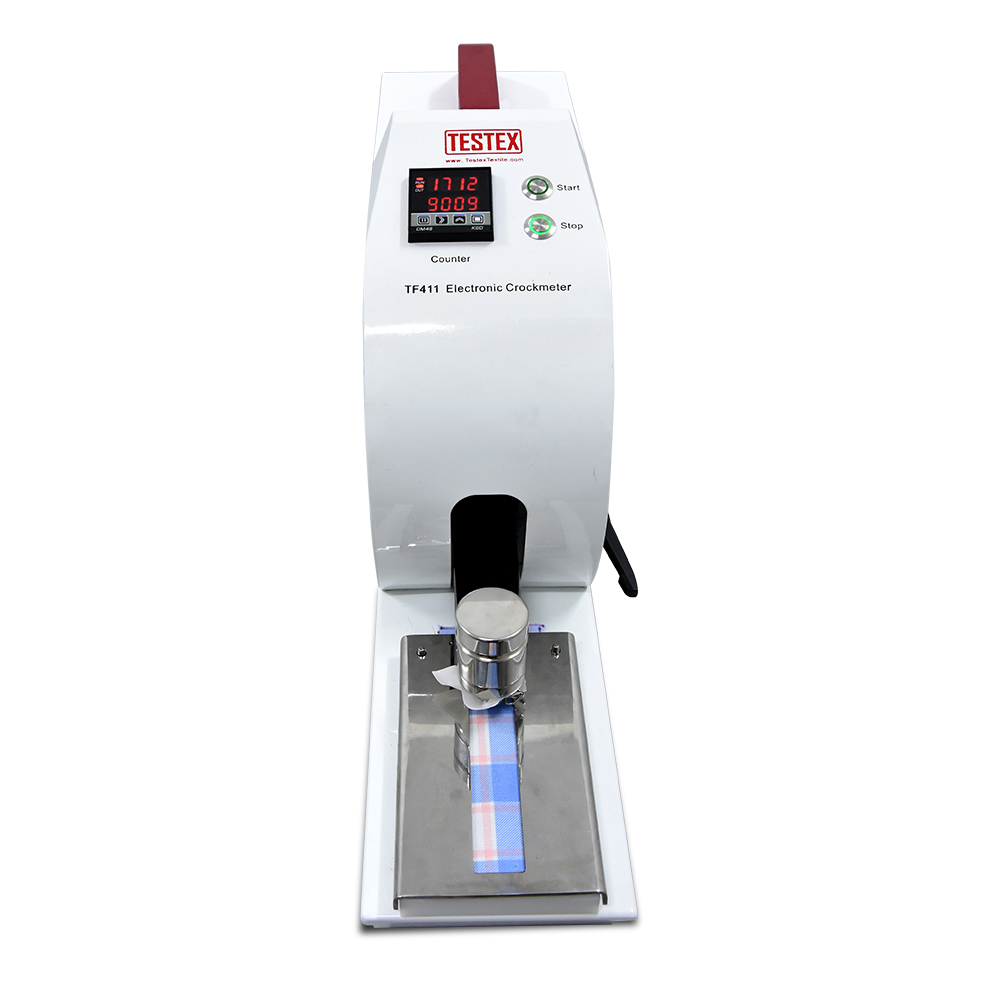

| Type of Crockmeter | TF411 Electronic Crockmeter | |

| Image |  |

|

| Rubbing head | 16 mm | |

| Vertical pressure | 9N+/-10% | |

| Rubbing stroke | 104 mm | |

| Counter | 1 ~ 999,999 times, automatically stop | |

| Net Weight | 11 kg | |

| Dimensions | 170 mm * 650 mm * 330 mm | |

| Power | 220/110 V 50/60 Hz 3 A | |

| Standards | ISO 105×12(circular rubbing head), GB/T 3920(circular rubbing head), AATCC8 ,ISO 20433 Method C | |

| Optional Standards | ISO 105xD02,ISO 105×12(rectangular rubbing head),GB/T 3920(rectangular rubbing head),AATCC165 |

Accessories

- AATCC rubbing clothing

- Sand paper

- Clamping sleeve

- Sampling plate

Optional Accessories

- AATCC/ISO rubbing cloth

- AATCC/ISO grey card

- Sandpaper

- Rectangular test heads and clamping rings

- Round clamping rings

Test Principle of Crockmeter TF411

The rubbing head (usually weighs 9N) runs with a standard speed in the friction cloth specimen, to do the standard length of reciprocal linear motion, after reaching the set number of times, the Crockmeter automatically stops running. Then use the gray sample card to assess the staining of the friction cloth, so as to assess the rubbing color fastness of the sample.

Application of Crockmeter TF411

The Crockmeter also named rubbing fastness tester, is mainly used in cotton, wool, hemp, silk, knitting, printing, and dyeing industries, the determination of various types of fabric color resistance to dry, wet friction color fastness.

Moreover, the Crockmeter rubbing fastness tester can apply to textiles made from all fibers in the form of yarn or fabric whether they are in the process of dyeing, printing, or coloring. However, it is unwise to use the Crockmeter for carpets or for prints. Because their singling out of areas may be too small to apply this method. Most importantly, we need to carry out the Crockmeter test before or after some treatments, such as washing, dry cleaning, washing, dry cleaning, shrinkage, ironing, finishing, and other processes about textiles. Otherwise, they may affect the degree of color transfer from a material, making it poor.

Besides, the Crockmeter is equipped with an electronic counter with a handle set on the top to take it easy. And it has a piece of sandpaper set under the test sample. Therefore, it is possible to fix the sample during the test, making the rubbing Color Fastness test repeatable. With the aid of a stable slide, the instrument can offer you even and precise testing results.

Except for the rubbing fastness tester, other color fastness equipment including the washing fastness tester, and light fastness tester, can check on this page by clicking here.

The significance of the color fastness resistance

As we can see, it is easy for the color of one piece of cloth to change and transfer to another cloth in the process of manufacturing, wearing, storage, etc., due to the rubbing. What is worst, wearing cloth with poor color fastness, not only will stain other light-colored clothing, affecting the beauty but also surface dyes will be easily transferred to the skin due to the rubbing. As a result, the skin will absorb the dye, causing allergies to the skin, or doing harm to the human body to some extent. Therefore, it is of great importance to test the color fastness resistance and improve it.

Welcome toTESTEX – a professional textile testing instrument supplier – Crockmeter TF411 is on sale, contact us to get a detailed price quote.