Standards

- ASTM D7094ASTM D6450

- IP620

- SH/T 0768

Correlation to

- ASTM D56

- ASTM D3828

- DIN 51758

- ISO 2719

- ISO 3679

- ISO 3680

- ISO 13736

- IP34

- IP170

- JIS K2265

Low Temperature Flash Point Testing

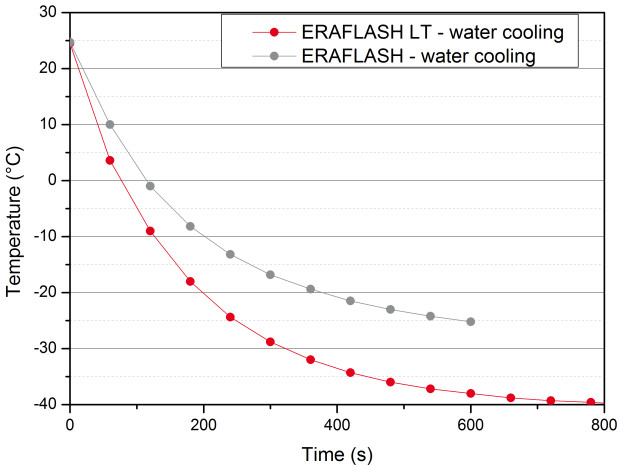

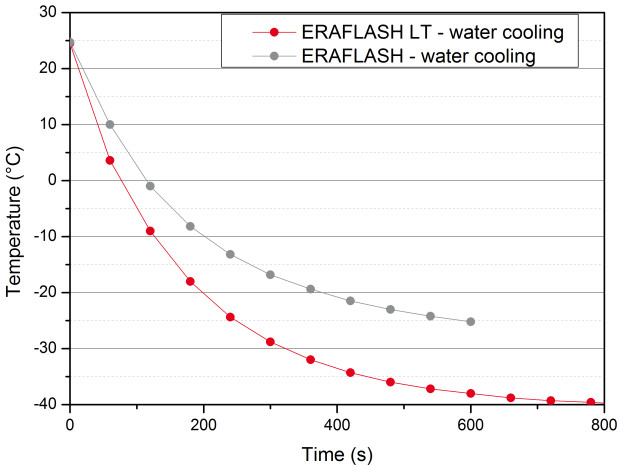

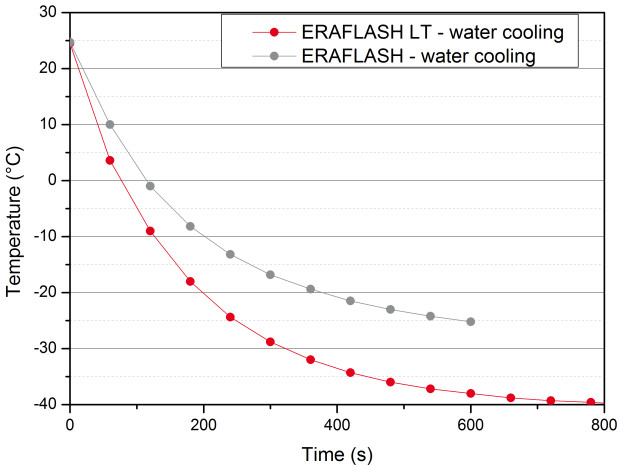

To increase sample throughput for low temperature flash point testing the ERAFLASH LT was equipped with stacked Peltier elements. This leads to three major improvements for low temperature flash point testing:

- The cooling speed of the instrument was increased by approximately 35%

- Without any external cooling temperatures approximately 35 °C below ambient temperature (e.g -15 °C) are accessible.

- With external water cooling low temperature flash point testing down to -40 °C oven temperature is possible

Now simple low temperature flash point testing is possible without the need to cool the equipment with dry ice or other substances.

Further Improvements for Low Temperature Flash Point Testing

ERAFLASH LT is equipped with a coolant valve that automatically shuts the coolant flow off if not needed. This helps to eliminate condensation of humidity on the cooler. Ice formation during cool down on the oven surface is prevented by using a cooling cup that shields the oven surface from the ambient air. It is also possible to cool the sample using ERAFLASH LT prior to the actual measurement.

Applications

ERAFLASH LT is the ideal partner if samples with flash points below ambient temperature or even below 0 °C are measured. According to ASTM D7094 and IP620 the flash point measurement needs to be started 18 °C below the expected flash point. For a sample like Ethanol with an expected flash point of around 12 °C the measurement needs to be started at -6 °C. Using ERAFLASH LT speeds up the analysis as it is optimized for low temperature flash point measurements. Flash points of crude oils, especially if they still contain volatile compounds, can reach flash points well below 0 °C. Industries with high sample throughputs such as the fragrances industry also profit from the fast turnaround time due to the increased cooling rate.

Measurement Procedure

Just four easy steps are required for a safe low temperature flash point testing at maximum precision:

- Enter sample ID and operator name

- Select the measurement standard and add additional parameters (e.g. expected flash point)

- Fill the sample cup with sample (1 mL or 2 mL), place the sample cup inside the measurement chamber, and close the door

- Press the RUN button

The instrument now visualizes the measurement procedure on the screen showing the sample and oven temperature as well as pressure gauge displaying the pressure increase after ignition. After the measurement the flash point temperature is corrected for the atmospheric pressure and rounded to the next 0.5 °C. The result will be saved in the corresponding result file. To improve the measurement further, it is possible to use a cooling cup to prevent ice formation during the cool down process.

Characteristics of the low temperature flash point testing can be seen in the Combustion Graphics™. This makes ERAFLASH LT the ideal solution for R&D as well as quality control.

ERAFLASH – Low-Temperature Measurements

Take a look at our latest video that demonstrates how easy low-temperature flash point testing can be done using ERAFLASH or the flashpoint autosampler tester ERAFLASH S10.

Low Temperature Flash Point Testing

To increase sample throughput for low temperature flash point testing the ERAFLASH LT was equipped with stacked Peltier elements. This leads to three major improvements for low temperature flash point testing:

- The cooling speed of the instrument was increased by approximately 35%

- Without any external cooling temperatures approximately 35 °C below ambient temperature (e.g -15 °C) are accessible.

- With external water cooling low temperature flash point testing down to -40 °C oven temperature is possible

Now simple low temperature flash point testing is possible without the need to cool the equipment with dry ice or other substances.

Low Temperature Flash Point Testing

To increase sample throughput for low temperature flash point testing the ERAFLASH LT was equipped with stacked Peltier elements. This leads to three major improvements for low temperature flash point testing:

- The cooling speed of the instrument was increased by approximately 35%

- Without any external cooling temperatures approximately 35 °C below ambient temperature (e.g -15 °C) are accessible.

- With external water cooling low temperature flash point testing down to -40 °C oven temperature is possible

Now simple low temperature flash point testing is possible without the need to cool the equipment with dry ice or other substances.

Further Improvements for Low Temperature Flash Point Testing

ERAFLASH LT is equipped with a coolant valve that automatically shuts the coolant flow off if not needed. This helps to eliminate condensation of humidity on the cooler. Ice formation during cool down on the oven surface is prevented by using a cooling cup that shields the oven surface from the ambient air. It is also possible to cool the sample using ERAFLASH LT prior to the actual measurement.

Further Improvements for Low Temperature Flash Point Testing

ERAFLASH LT is equipped with a coolant valve that automatically shuts the coolant flow off if not needed. This helps to eliminate condensation of humidity on the cooler. Ice formation during cool down on the oven surface is prevented by using a cooling cup that shields the oven surface from the ambient air. It is also possible to cool the sample using ERAFLASH LT prior to the actual measurement.

Applications

ERAFLASH LT is the ideal partner if samples with flash points below ambient temperature or even below 0 °C are measured. According to ASTM D7094 and IP620 the flash point measurement needs to be started 18 °C below the expected flash point. For a sample like Ethanol with an expected flash point of around 12 °C the measurement needs to be started at -6 °C. Using ERAFLASH LT speeds up the analysis as it is optimized for low temperature flash point measurements. Flash points of crude oils, especially if they still contain volatile compounds, can reach flash points well below 0 °C. Industries with high sample throughputs such as the fragrances industry also profit from the fast turnaround time due to the increased cooling rate.

Applications

ERAFLASH LT is the ideal partner if samples with flash points below ambient temperature or even below 0 °C are measured. According to ASTM D7094 and IP620 the flash point measurement needs to be started 18 °C below the expected flash point. For a sample like Ethanol with an expected flash point of around 12 °C the measurement needs to be started at -6 °C. Using ERAFLASH LT speeds up the analysis as it is optimized for low temperature flash point measurements. Flash points of crude oils, especially if they still contain volatile compounds, can reach flash points well below 0 °C. Industries with high sample throughputs such as the fragrances industry also profit from the fast turnaround time due to the increased cooling rate.

Measurement Procedure

Just four easy steps are required for a safe low temperature flash point testing at maximum precision:

- Enter sample ID and operator name

- Select the measurement standard and add additional parameters (e.g. expected flash point)

- Fill the sample cup with sample (1 mL or 2 mL), place the sample cup inside the measurement chamber, and close the door

- Press the RUN button

The instrument now visualizes the measurement procedure on the screen showing the sample and oven temperature as well as pressure gauge displaying the pressure increase after ignition. After the measurement the flash point temperature is corrected for the atmospheric pressure and rounded to the next 0.5 °C. The result will be saved in the corresponding result file. To improve the measurement further, it is possible to use a cooling cup to prevent ice formation during the cool down process.

Characteristics of the low temperature flash point testing can be seen in the Combustion Graphics™. This makes ERAFLASH LT the ideal solution for R&D as well as quality control.

Measurement Procedure

Just four easy steps are required for a safe low temperature flash point testing at maximum precision:

- Enter sample ID and operator name

- Select the measurement standard and add additional parameters (e.g. expected flash point)

- Fill the sample cup with sample (1 mL or 2 mL), place the sample cup inside the measurement chamber, and close the door

- Press the RUN button

The instrument now visualizes the measurement procedure on the screen showing the sample and oven temperature as well as pressure gauge displaying the pressure increase after ignition. After the measurement the flash point temperature is corrected for the atmospheric pressure and rounded to the next 0.5 °C. The result will be saved in the corresponding result file. To improve the measurement further, it is possible to use a cooling cup to prevent ice formation during the cool down process.

Characteristics of the low temperature flash point testing can be seen in the Combustion Graphics™. This makes ERAFLASH LT the ideal solution for R&D as well as quality control.

ERAFLASH – Low-Temperature Measurements

Take a look at our latest video that demonstrates how easy low-temperature flash point testing can be done using ERAFLASH or the flashpoint autosampler tester ERAFLASH S10.

ERAFLASH – Low-Temperature Measurements

Take a look at our latest video that demonstrates how easy low-temperature flash point testing can be done using ERAFLASH or the flashpoint autosampler tester ERAFLASH S10.