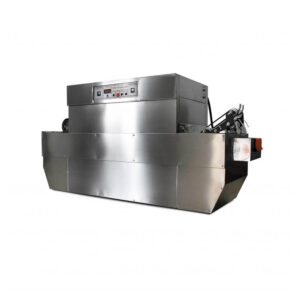

Lab Padder, a floor type padding mangle for dyeing, finishing and Impregnating. We provide the professional vertical padder, please contact us if you are interested in it.

Description

Application

Lab Padder plays a very important role in the process of textile dyeing, finishing, and impregnating. The lab padder can smoothly and evenly roll out the excess water in the fabric and reduce energy consumption during drying.

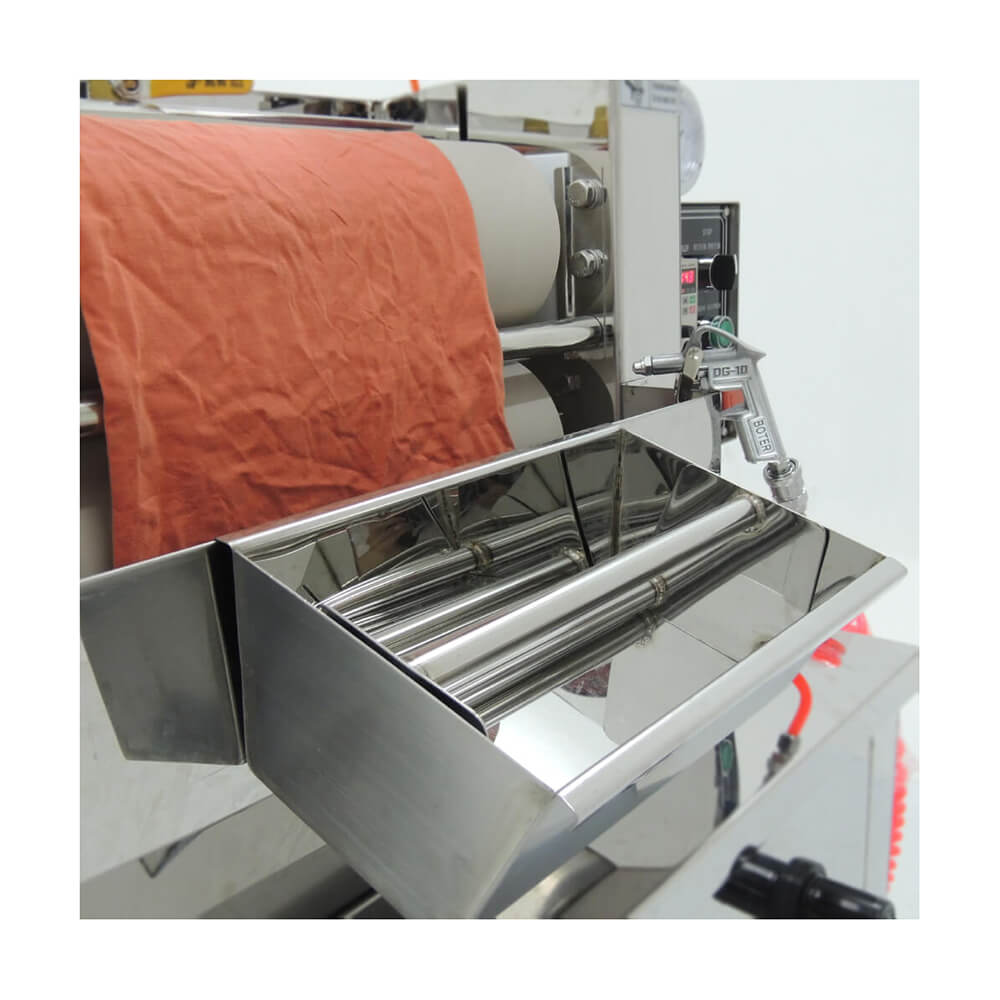

The material of the lab padder roller is high-quality NBR, good flexibility ensures long life. The main components are all the best in the world. The lab padder has an emergency button and a knee pedal to stop the machine’s operation. We can provide air compressors on request.

Specifications

- Roller length: 420mm ( 600 mm customized)

- Roller Dia.: Φ130 mm

- Shore hardness: 70°±5°

- Working speed 0 ~ 18 rpm (Adjustable)

- Air pressure: 0.1 ~ 0.6 Mpa

- Stainless steel

Weight

| 125 kg |

Power

| 220 V | 50 Hz |

Dimensions

| Length: 890 mm | Width: 610 mm | Length: 1250 mm |

What can a lab padder do for you?

The padding machine is used to pad chemical reagents such as dyeing liquid. After padding the fabric, in addition to ensuring a certain margin rate. It is also necessary to ensure that the liquid in the fabric is evenly distributed.

The uniformity of the rolling liquid in the warp direction of the fabric mainly depends on the stability of process parameters such as vehicle speed and rolling pressure during the padding process, while the uniformity of the rolling liquid in the weft direction of the fabric is mainly related to the structure of the rolling car, especially the roll.

Rolling Evenness The rolling uniformity of the fabric in the weft direction, referred to as rolling uniformity. It is expressed by the relative error of the overage rate of each point upward of the fabric weft. In the actual production process, select the fabric right in three places (left, center, right), and test the mangle expression for comparison. General mangle expression should be <2%, assuming that between 2% and 5%, the process conditions can be adjusted to compensate. If >5%, generally can not make up.

Factors affecting the uniformity of the padding machine

There are many factors that affect the uniformity of the padding machine, such as rolling pressure, roll hardness & stiffness. Since the roll’s stiffness is the main structural factor affecting the uniformity of the rolling liquid, improving the stiffness is the fundamental measure to improve the uniformity of the rolling liquid. Considering the roll structure, the deflection of the roll should be reduced as much as possible without excessively increasing its cross-section to improve the uniformity of the rolling liquid. For example, we can use different structural forms, such as medium-high rolls, pre-bending rolls, medium-support rolls, and medium-solid rolls, in order to reduce the deflection of the rolls and ensure the uniformity of the rolling mill in the weft direction.

Welcome to TESTEX – a professional textile testing instrument supplier – lab padder is on sale, contact us to get a detailed price quote.