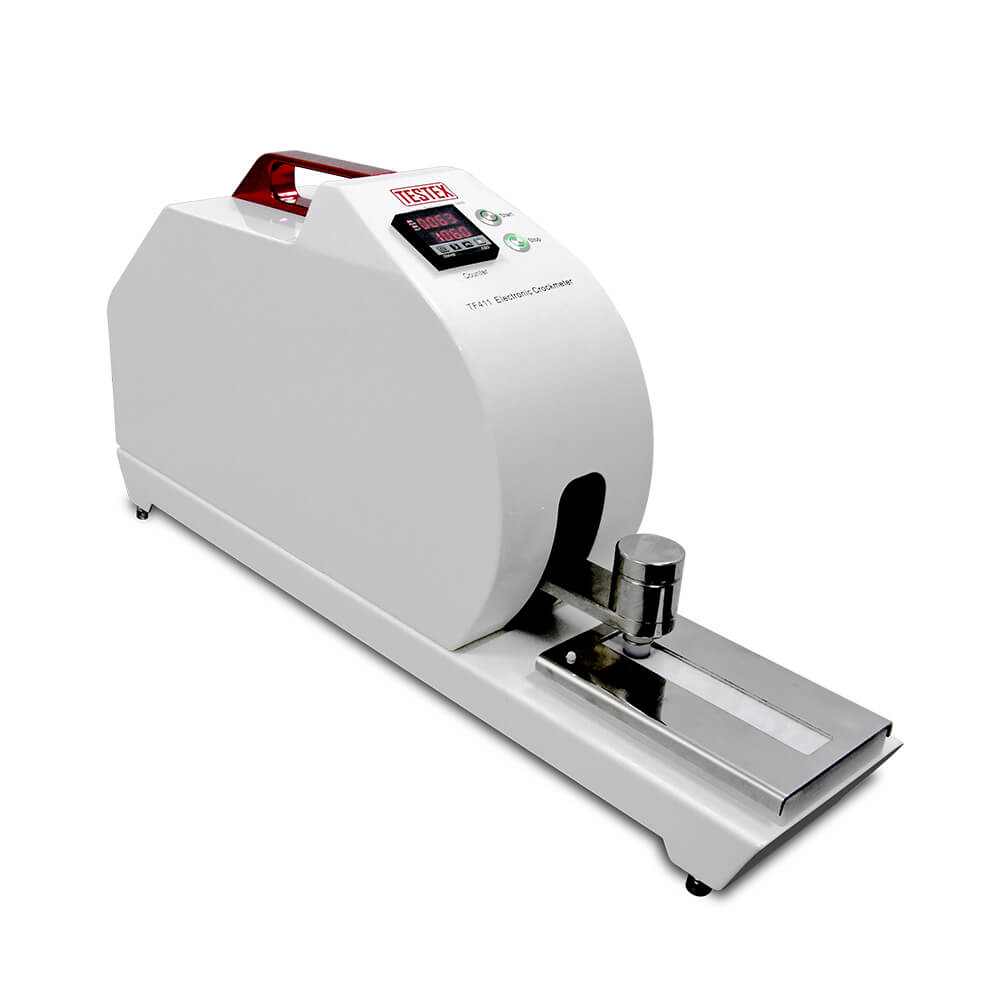

Rotary Crockmeter,is used to evaluate the degree of material damage and surface color transfer after dry or wet abrasion,or to determine the colour fastness of textiles to dry or wet rubbing.It is mainly applied to shoe upper materials such as leather, plastic and textile. It can also be used to evaluate the fastness to rubbing of printed lettering on the surface of shoes.The principle of the test is to use a round wool felt (dry or wet) to press the sample with a fixed weight, and the wool felt is rotated to rub the sample.After a fixed number of rubbings, the degree of discoloration of the samples was evaluated by a standard gray card.

Description

Application of Rotary Crock Meter TF412

Rotary Crockmeter, is a special crock meter for testing the color fastness(to dry or to web rubbing) of textiles, particularly for leather, plastic, and textile or printer fabrics, fabric crocking, features in rotary movement.

The rotary crock meter applies 1134 grams of pressure on a 16mm testing head and rotates 1.125 turns clockwise and then anti-clockwise. In a word, it is one of the friction testers, or crocking test machines, which has been widely used in the crocking test.

Features of Rotary Crock Meter TF412

Convenient operation. Touch screen control, Chinese and English menu, human-machine dialogue mode, convenient operation.

Practicality. Free to set the number of friction, can be forward and backward counting can set the rotational friction time, to the set value automatically stop.

Accurate testing. Standard round friction head, smooth friction contact, sample clamp made of spring steel, ensure fast fastening of samples and reproduce results. The perfection of details is the only way to achieve accurate testing.

Durable. Mechanical components are made of non-corrosive construction and stainless steel parts for long life and cost savings.

Specifications of Rotary Crock Meter TF412

- Rubbing head: Dia.16mm&25mm

- Vertical pressure: 1134g

- Rotation: 1.125turns

Standard Accessories

1 AATCC rubbing cloth

2 Sandpaper

3 Clamp ring

4 Weight

5 Compression ring

Optional Accessories

1 AATCC/ISO rubbing cloth

2 ATCC/ISO Gray Scale for Staining

3 Sandpaper

Weight

| 20 kg |

Dimensions

| Length: | 280 mm | Width: | 150 mm | Height: | 250 mm |

Standards of Rotary Crock Meter TF412

| AATCC 116 | ISO 105×16 |

The testing procedure of Rotary Crock Meter TF412

Dry abrasion color fastness test

1) Install a piece of wool felt on the test bench and fix its position.

2) Cut a piece of test cloth from the standard white cotton cloth, place a piece of circular fitting on the wool felt, place the test cloth, i.e. the sample, on top of the circular fitting, and adjust the sample position so that the friction head can touch the part of the sample to be rubbed.

3) Install a weight on the upper end of the instrument so that the vertical rod can apply 1143g of pressure to the sample.

4) Turn on the switching power, wait for the display to start, set the speed and time, and press the start button, the wool felt and the sample will start to rub alternately clockwise and counterclockwise.

5) When the time condition is reached, the instrument stops rotating, removes the weights, and takes out the sample and the wool felt for testing. The sticky color of the wool felt is evaluated.

6) For evaluation, place the tested white cotton felt on 3 layers of white cotton cloth of the same material.

The color fastness of the sample is evaluated using AATCC color cards or tinted gray cards.

Wet abrasion color fastness test

1) Wetting of the sample: Wet the sample with distilled water and pass the sample between filter papers through the squeezer, or remove excess water by any other convenient means.

2) The rest of the procedure is the same as dry abrasion.

3) After the wet state test is completed, the sample should be allowed to dry naturally in the air before the evaluation of the sample.

Recording

1) It should be recorded that: the degree of sticky color at the rounded edges will be more severe than at the center of the circle 2) Evaluate the degree of sticky color at the rounded edges.

3) Classify the results of the wet and dry tests separately. 4) Indicate whether the wet or dry test was performed. 5) Indicate whether gray or colored cards were used for the evaluation.

For more crock meter test methods, please contact us.

Why Choose TESTEX Rotary Crock Meter TF412

Strictly meet standards

All data for the TF412 fabric crocking machine meet the standard parameters.

Consistency with international third-party laboratories

The test data are comparable to the test results obtained by well-known international third-party laboratories.

High repeatability

With the same set of samples, and the same machine, and after multiple tests, the results are consistent.

High reproducibility

With the same set of samples, and different machines of the same model, after multiple tests, the results are consistent.

Longer service life

TESTEX makes prototypes and then subjects them to rigorous reliability testing in a variety of environments to ensure achieve the expected service life.

User-friendly transparent warranty policy

Textile testing machines, 14 months free warranty (12 months normal warranty time + 2 months shipping time). Besides, all spare parts, have 3 months free warranty.

We provide full life-cycle support for Crock Meter Rotary TF412, and other crocking test machines, So feel free to contact our service team with any questions you may have.