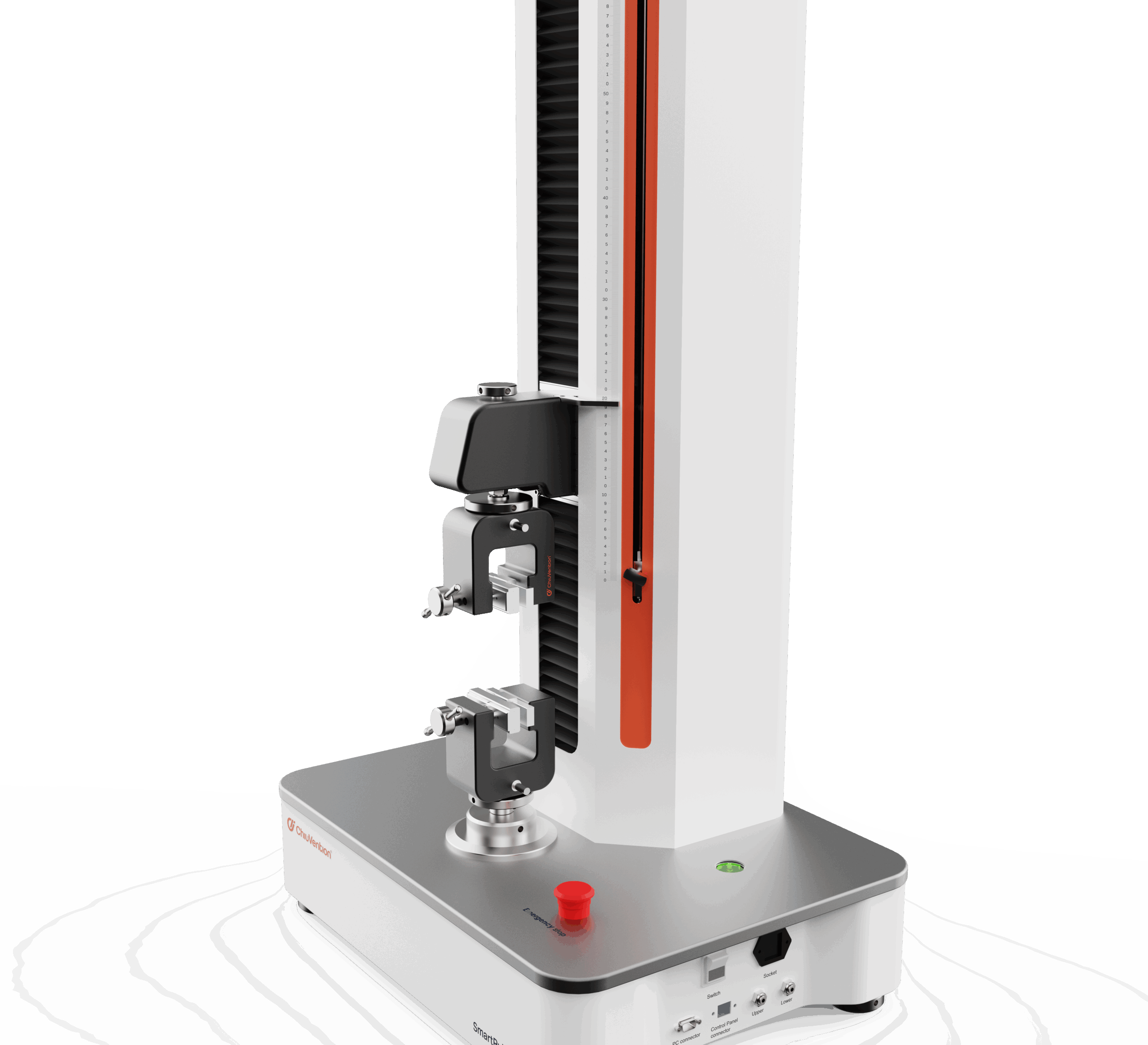

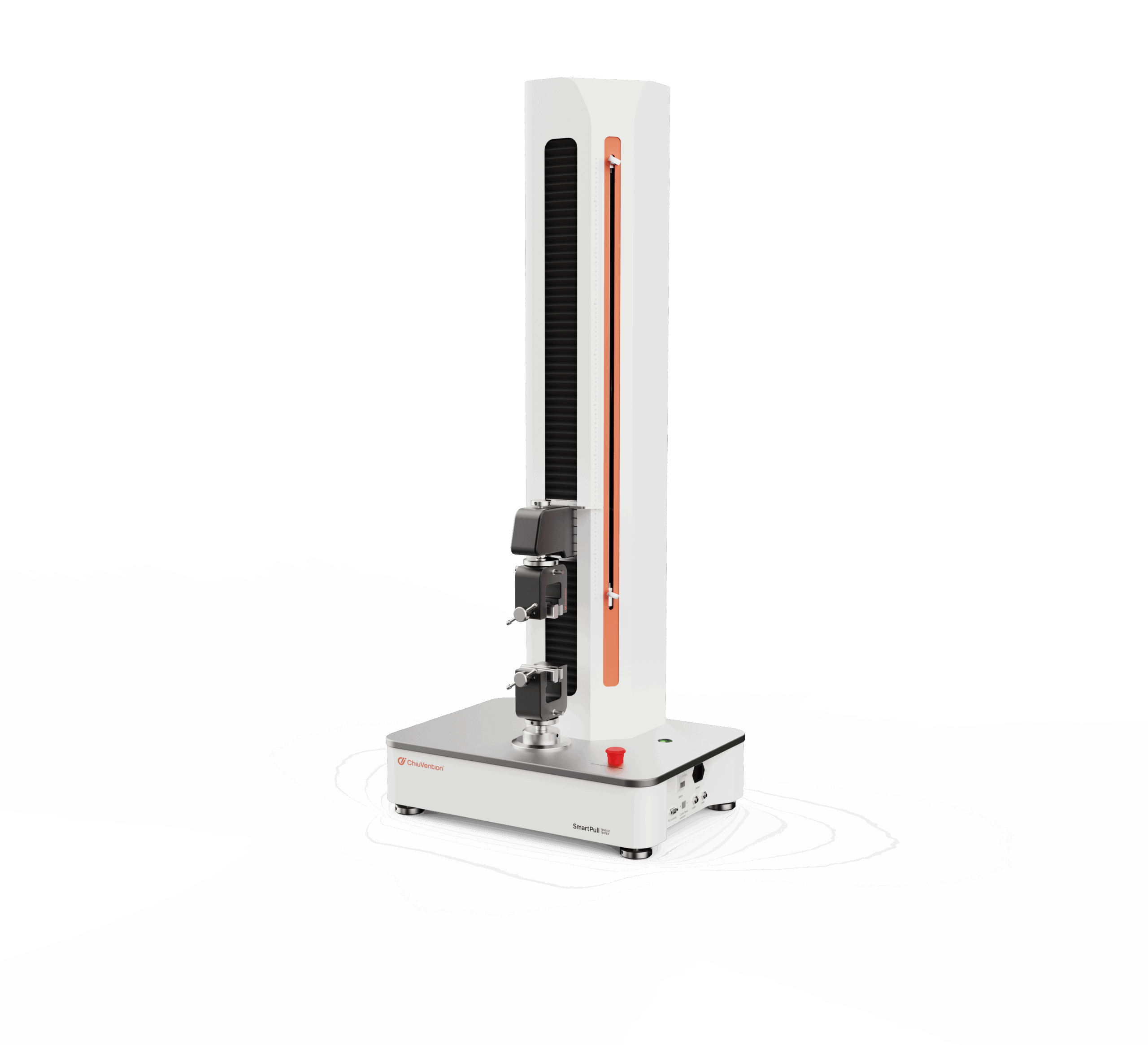

The Universal Tensile Tester, also known as a Tensile Strength Tester, Universal Testing Machine (UTM), or Universal Tensile Testing Machine, is a highly accurate and reliable AC servo-driven device designed for various material testing applications, such as textiles, leather, footwear, etc. Equipped with precision ball screws, this pull tester ensures stable pulling force, enhancing both the stability and accuracy of the test results.

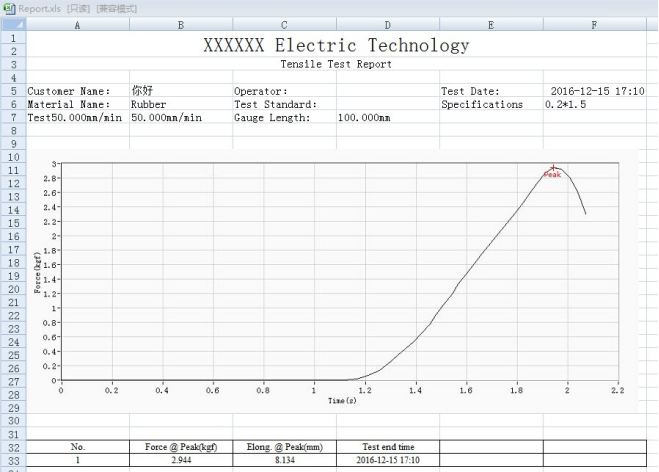

The Tensile Testing Equipment features robust software compatibility that delivers detailed test metrics, including displacement, maximum force, elongation, and stress, to meet diverse testing needs. With a focus on safety, the fabric tensile tester incorporates various safety designs to protect both the instrument and the operator during use.

Designed to meet international standards such as ISO 9073-3, ISO 13934-1/2, ASTM D5034, ASTM D5035, ISO 3377-2, ISO 13937-3, FZ/T 01030, and GB/T 19976, this Tensile Strength Equipment ensures compliance with global testing requirements. With different fixtures, the tensile tester can easily accommodate various materials, offering flexible testing options across numerous industries.

Description

Features of Fabric Tensile Tester

Higher testing accuracy

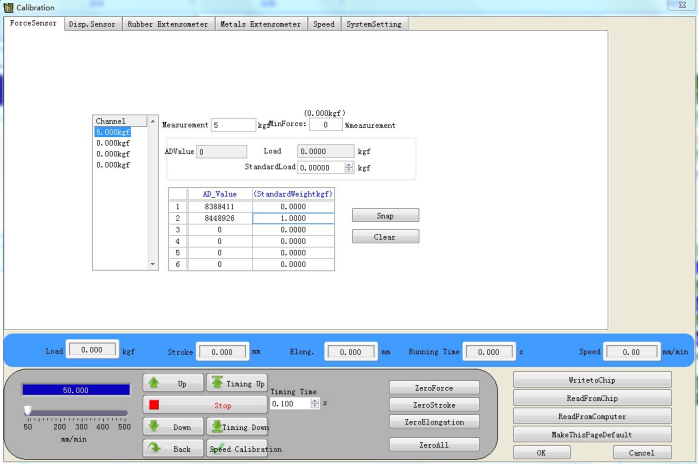

AC servo drive and ball screw achieve stable and constant pulling force, with force accuracy within 1%, so SmartPull Tensile Tester ensures the reliability and repeatability of tensile test results.

Safety guarantee for the whole testing process

The SmartPull Fabric Tensile Strength Tester is equipped with an intelligent and active displacement and torque alarm system, an overload and emergency stop device, and an up-and-down travel limiting device, this tensile testing machine always keeps the testing process safe and stable.

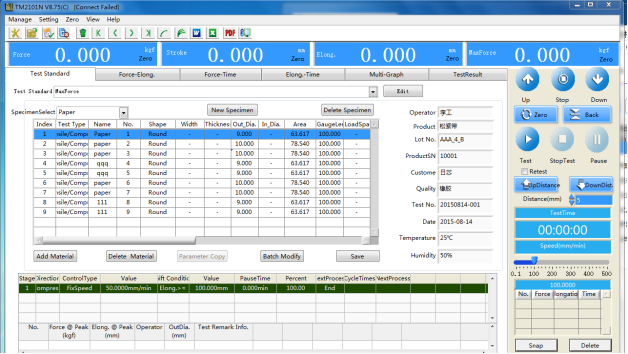

Powerful software

The test software of this Universal Tensile Testing Machine can be applied to different languages and can present the displacement, maximum force, elongation, stress, maximum stress, bending stress, speed, and other test results. That is, getting a more comprehensive and objective evaluation of textile properties.

Applicable up to a series of standards

This Tensile Strength Tester applies to many testing standards, such as ISO 3377-2, ISO 13934-1/2, ISO 13937-2/3, ISO 20932-1, ASTM D5034, ASTM D5035, ASTM D5587, GB/T3917.2, FZ/T 01030, ISO 9073-4, ISO13934-1/2, ISO 9073-3, ISO 13937-2/3, ISO 4674-1, GB/T 3917.4, GB/T 3923.1, ISO 2062, ASTM D6797, GB/T 19976.

Easy operation

SmartPull Tensile Tester is very easy to operate. Multi-functional pneumatic gripper, just replaces the clips to complete different tests, easy and quick to replace. Tensile tests and top-breaking tests do not need to replace the sensor.

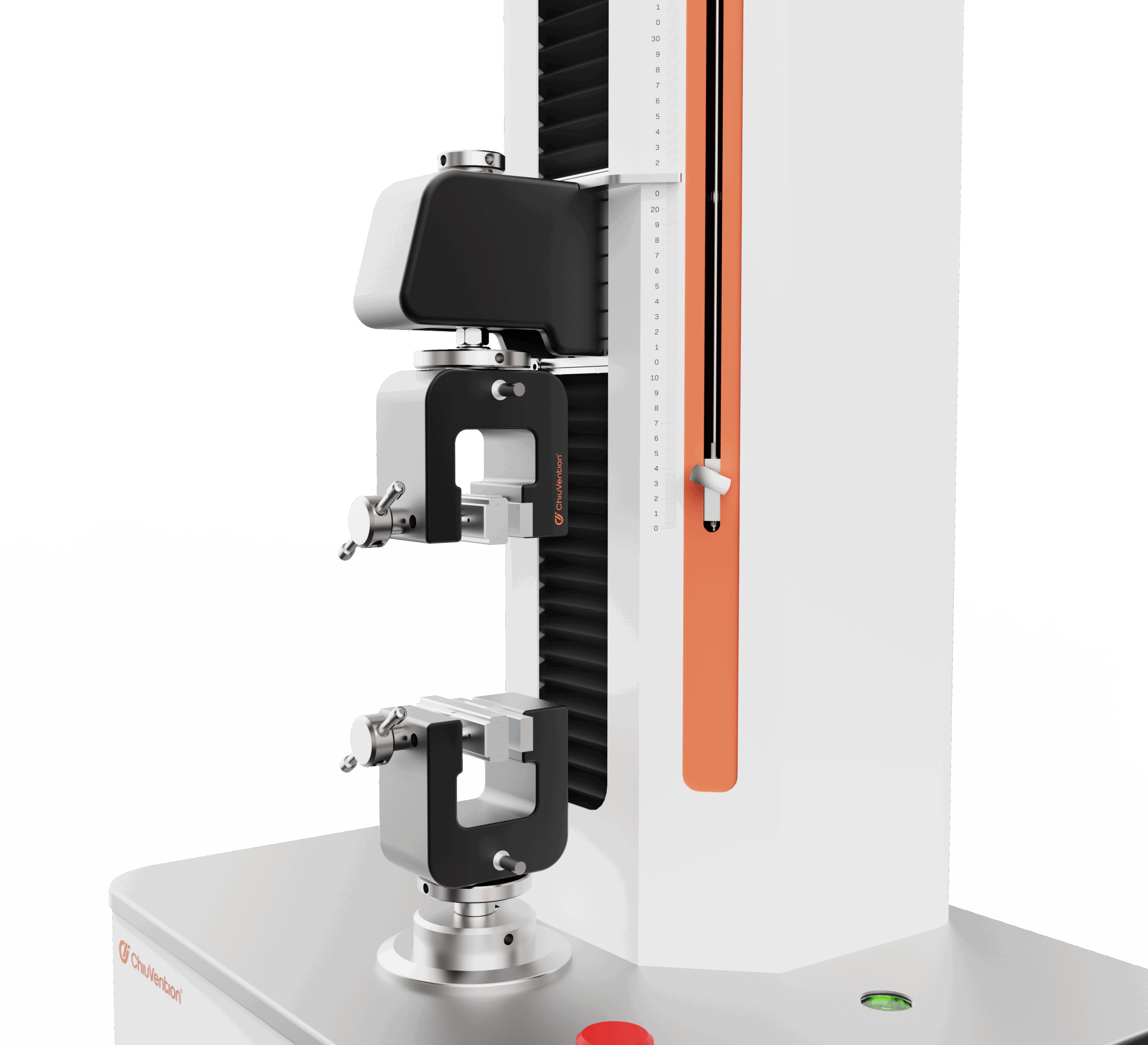

Unique design

SmartPull Tensile Tester has a unique appearance design combined with a sense of technology, a scratch-resistant surface, and it is durable.

User-friendly

The side-cutting design is user-friendly and space-efficient, allowing for more effective measurement of tensile strength in textiles.

Application of Fabric Tensile Tester

This Universal Tensile Tester is specifically engineered for testing textiles, leather, footwear, rubber, laminated films, packaging materials, pipes, woven tapes, composite materials, and more. It is capable of conducting a wide range of tests, including tension, compression, bending, tearing, shearing, peeling, and top-breaking tests. TESTEX is a trusted tensile testing machine manufacturer, with our products currently in use across more than 60 countries and regions worldwide. Additionally, we offer dual-column tensile testers for applications requiring higher capacity testing.

Specification of Fabric Tensile Tester

Test capacity: 250kg, 500kg is optional and the appearance will change

Test level: Class 1

Max travel: 800 mm (without fixture)

Travel accuracy: ≤1%

Traverse speed: 1mm/min ~ 500mm/min

Speed accuracy: ≤1%

Test force range: 0.2%~100%FS

Force accuracy: ≤1%

Software configuration (standard):

version A of the test system, with a single-step test

Software configuration (optional):

Version C of the test system can achieve a multi-step test

Power 220 /110V 50/60Hz

Weight 90kg

Dimension 630*460*1470 mm (D*W*H)

Fixture and standards

Version A :

ISO 9073-3, ISO 13934-1, ISO 13934-2, ASTM D5034,

ASTM D5035, GB/T 3923.1, GB/T 3923.2

GB/T 13773.1, GB/T 13773.2, GB/T 24218.3

(The standards above are matched with clamps by 25×25 mm, 25×50 mm,

25×75 mm)

Optional Fixture and standards

Clamps by 25×100 mm: ISO 9073-4 GB/T 3917.3

Clamps by 50×75 mm : ASTM D5587

Leather tearing fixture: ISO 3377-2

Top breaking fixture: ASTM D6797 FZ/T 01030 GB/T 19976

Yarn fixture: ISO 2062

Version A+: ISO 13937-2 (Sample 50 mm wide)ISO 13937-3

GB/T 3917.2 (Sample 50 mm wide) GB/T 3917.5

Clams by 25×200 mm: ISO 13937-4 ISO 4674-1 GB/T 3917.4

Version C: ISO 13936-2, ASTM D4964 (U type fixture)

VersionC+: ASTM D434 ASTM D1683 ISO 13936-1

ISO 20932-1( with linear clamps, or choose other fixtures and replace the

clamps)

(The standards above should be programmed according to the test requirements provided by customers.)

Accessory

Standard accessories: pins, operation manuals, power cords, communication cords, control panels, fuses

Optional accessories: sampling plate

Computer Configuration (Optional)

- CPU for the Intel Celeron (Celeron) 2GHz or more CPU

- Memory at least 512MB, more than 1GBis better

- Hard disk space of more than 2GB

- Display resolution of 1024 × 768 or more.

- Printer compatible with the operating system (if output reports are required)

- An applicable operating system for Microsoft’s Windows XP, Windows 7, Windows 8, Windows 10

- If you need to output the report in Word and Excel format, you should install Microsoft’s Microsoft Office 2003, 2007, and 2010 versions of the software.

Why Choose Our Tensile Tester

Strictly meet standards

All data for the tensile tester meet the standard parameters.

Consistency with international third-party laboratories

The test data are comparable to the test results obtained by well-known international third-party laboratories.

High repeatability

With the same set of samples, and the same tensile testing machine, and after multiple tests, the results are consistent.

High reproducibility

Whether with the same set of samples, or different machines of the same model, after multiple tensile strength tests, the results are consistent.

Longer service life

For all the tensile machines manufactured by ChiuVention, before mass production, prototypes are made and required to pass the strict Reliability Test, i.e. tested under challenging environments such as high and low temperature, high speed, and high load, etc., to ensure the expected serving life no less than 10 years.

User-friendly transparent warranty policy

Textile testing machines, 14 months free warranty (12 months normal warranty time + 2 months shipping time). And all spare parts, 3 months free warranty.

We provide full life-cycle support for universal tensile testing machines, so feel free to contact our service team with any questions you may have.

How to Choose a Tensile Tester?

1. The universal tensile testing machine should be selected according to the standard adopted and the region where it is sold.

Because different regions adopt different standards, usually, European customers widely accept the ISO standard system, American customers widely recognize the AATCC and ASTM standard system, while Japanese customers are more inclined to the JIS standard system. Generally, fabric tensile tester machine manufacturers will indicate in the product manual which standards apply, certainly, you can consult the manufacturer.

2. Consider the tension range of the test material (maximum tensile strength).

The difference in the tension range of the test material will determine the size of the sensor, and the structure of the tensile strength testing machine, but of course, this has little effect on the price (except for the double column type). For general tensile textile testing, a maximum tension of 200N is sufficient. Therefore, the purchase of a single-column tension machine can be. TESTEX universal tensile machine maximum tension of 2500N, a broader range of applications; if the maximum tension needs to exceed 5000N should choose a double-column type.

3. According to the test, one needs to choose the appropriate maximum stroke.

Usually, the maximum stroke is the distance between the upper and lower fixture (test stroke) + the height of the upper fixture + the height of the lower fixture + the height of the sensor. Because different test materials will need different fixtures, choose a good fixture to know the specific test stroke. In general textile testing, the stroke in 600-800mm can be. Material elongation of more than 1000% can be selected stroke 1000 or 1200mm.

For more information about the cost of a tensile testing machine, please reach out to us to inquire about discounts on our fabric tensile testers. We also offer a variety of pull tester machines.

Besides, you can also learn more about our sister textile testing machine brand.