A yarn Appearance Board Winder, or yarn evenness tester, yarn appearance tester is used to test the yarn’s physical performances, such as the evenness, hairiness, neps, and so on. It is the use of a clamp on the instrument of the blackboard, shaken cotton, and chemical fiber yarn, with the uniformity of the blackboard to test the cotton impurities, dryness, and evenness, it is one of the main instruments to monitor the quality of yarn products.

Description

Application of Yarn Appearance Board Winder TY380

Yarn Appearance Board Winder measures the yarn’s physical properties, such as hairiness, neps, and other possible imperfections, to determine evenness and appearance. This machine complies with ASTM D2255 and can evaluate the appearance of most yarns, such as combed cotton yarns.

Finally, we can figure out whether the sample is qualified by comparing its appearance quality with that of the standard sample. The application scope of the test method also includes rotor spinning. However, it can not be used to test the appearance quality of woolen yarn.

Note: don’t include assessment against photographic comparison standards.

Features of Yarn Appearance Board Winder TY380

Aluminum alloy casting housing, black plate rotation with the speed control system, there are 7 speed adjustable, adapt to a wide range of yarns, overcome the drawbacks due to too fast speed for stranded yarns, low twist yarns, small force value yarns, etc. can not be tested,

and there are six shaking yarn densities, 7, 9, 11, 13, 15, and 19 wraps/cm, formed by the six-speed pulley replacement belt on the control box.

Specification

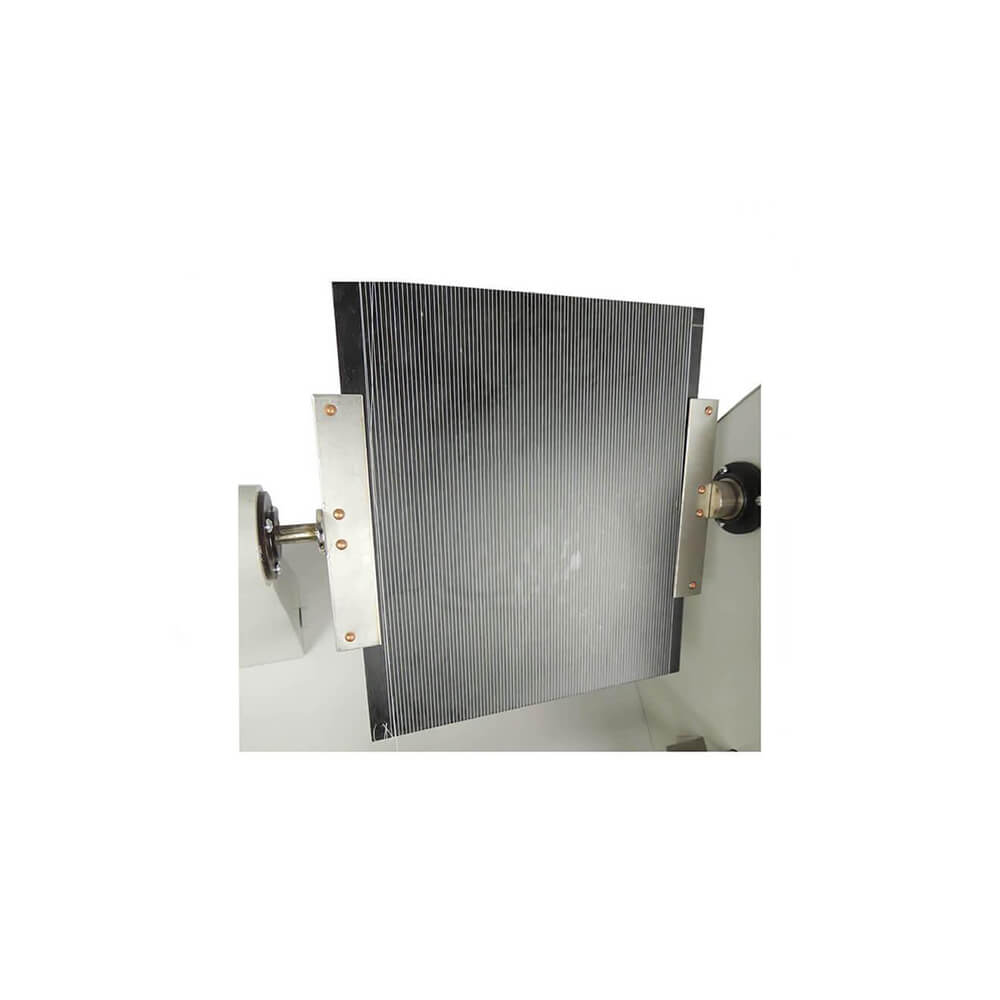

- Blackboard: 250mm × 180mm × 2mm

- Yarn winding density: 7, 9, 11, 13, 15, 19wraps/cm

- Rotation speed: 7 gears (adjustable)

Standard Accessories

Blackboard, Belt

Optional Accessories

Blackboard

Weight

| 30 kg |

Power

| 220/110 V | 50/60 Hz |

Dimensions

| Length: | 620 mm | Width: | 490 mm | Height: | 360 mm |

Standards

| ASTMD 2255 | GB 9996 |

Principle of Yarn Appearance Board Winder

The Yarn Appearance Board Winder consists of two major parts: the winding of the chalkboard and the horizontal movement of the yarn on the chalkboard.

The winding of the blackboard is mainly done by the left and right blackboard clamps.

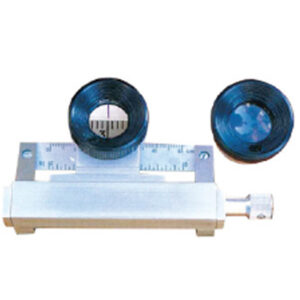

The lateral movement of the yarn on the blackboard is done by the axial displacement of the bridge-shaped half-nut on the screw. The winding density of the instrument has a variety of options, in order to make the instrument winding speed run smoothly, the choice of two smooth running, speeds should be a good DC servo motor to drive the blackboard winding and yarn transverse movement respectively.

To select the speed of winding density, the instrument uses a simple transformer tap to achieve different output voltages, through rectification to meet the armature voltage required by the DC motor, so as to achieve the purpose of changing the DC motor speed to meet the speed requirements of various winding densities.

To meet the above requirements, the apparatus through the control apparatus that when the apparatus is started, the armature windings of the two motors are powered at the same time, the winding of the blackboard and the yarn transverse motion to form a composite movement, so that the yarn is uniformly arranged on the blackboard and the selected density. When the blackboard is full of yarn winding, the magnetic separation piece fixed on the inserting frame is inserted between the magnet and the reed switch, which makes the reed switch move and de-energizes the relay, so that the two motors are de-energized at the same time and the instrument stops working automatically. Then the appearance grade of the yarn is judged on the blackboard.

How to Use TESTEX Yarn Appearance Board Winder?

You can see there are 5 tapered aluminum black yarn boards 220 x 180 mm on their surface. It can also provide a variable pitch traverse of 7-19 wraps per centimeter. In addition, its adjustable winding speed drive is available.

Before the testing, you should pick the representative samples from yarns by random sampling instead of sampling from the fixed machine or spindle. As we can see, the effect of the yarn appearance is directly reflected on the fabric surface. If the yarn’s appearance is of poor quality, the fabric quality will also be at a low level. Therefore, it is of great significance for you to buy a Yarn Appearance Board Winder which can assist you to determine the quality of the yarn appearance. When you purchase it, you can make your choice based on its structure, function, and mostly its accuracy to check the quality of the yarn’s appearance.

Welcome to TESTEX – a professional textile testing instrument supplier – Yarn Appearance Board Winder TY380 is on sale, contact us to get a detailed price quote.