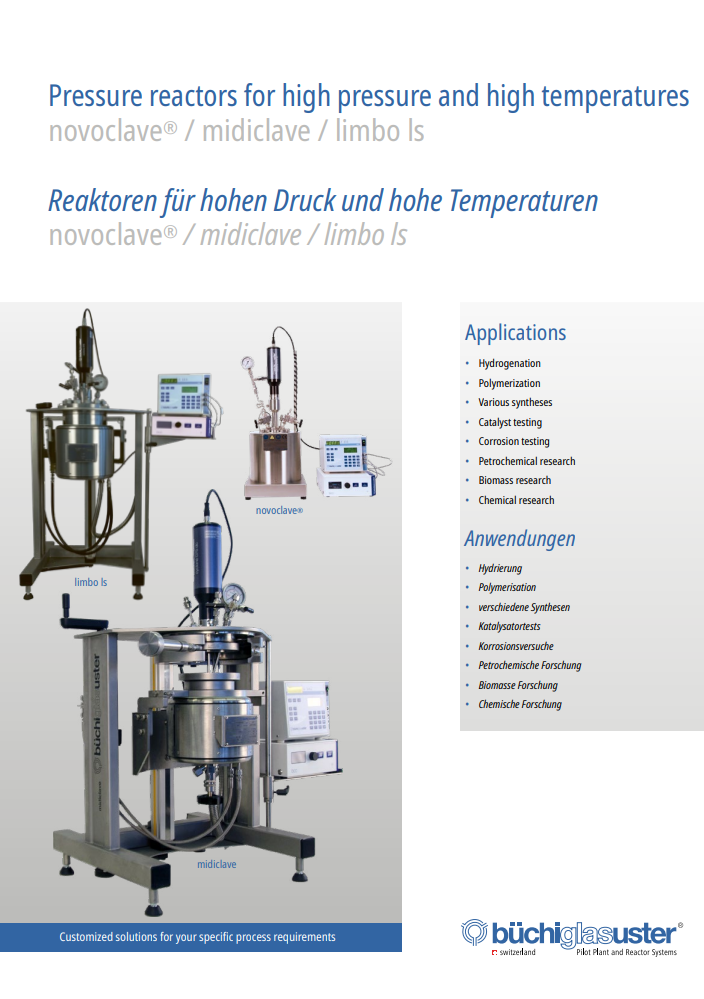

Laboratory high pressure reactor system

Reactor volume: 0.1 – 1.0 liter

Pressure: -1 (FV) to +200 bar

Temperature: -20 °C to +300 °C

Material: stainless steel, Hastelloy®

Other materials, pressures & temperatures are available

This high pressure reactor system is designed for the use of interchangeable steel pressure vessels. Safety features guarantee safe reactions under pressure.

The stainless steel or Hastelloy® reactors ensure high resistance against acids. Visual process control and monitoring is also possible under high pressure by using steel pressure vessels with sight glasses.

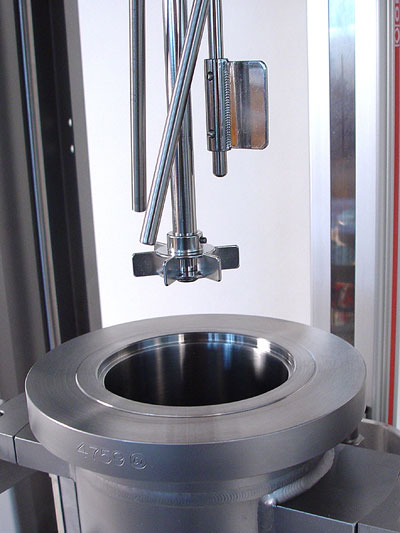

Various low to high torque magnetic drives ensure efficient mixing and stirring low to high viscosity process media as well as excellent heat transfer. The fast action closure and vessel lift makes changing vessels quick and easy without the use of tools.

The modular setup of the midiclave system allows changing or upgrading for new tasks at any time.

A wide range of accessories for feeding of liquids, solids, gas, a fast action closure device, reactor lift and others like catalyst baskets etc. are available – talk to us to define the right setup for your specific need.

Standard package

- Stand with open access from all sides

- Reactor Lift

- Special Safety Fast Action Closure (FAC)

- Pressure vessel (Type 3 & 4) with suitable stirrer shaft, stirrer, baffle, Pt-100 and bottom valve

- Cover plate with 7 openings and standard setup

- Swagelok fittings with bursting disc, manometer and 2 valves

- Stirrer drive cyclone 075 with integrated magnetic coupling, incl. controller cc075

- Tools and spare parts

Standard options

- cyclone 300 magnetic stirrer drive

- ATEX stirrer drive

- Electric heating / water cooling

- Measure and control systems

- Wide range of accessories

- Floor stand

Type 3

Metal

0.1, 0.25, 0.5, 1.0 liter

300 °C

200 bar

Type 4

Metal/Sight glass

0.5, 1.0 liter

300 °C

200 bar

Type 3E

Metal

0.1, 0.25, 0.5, 1.0 liter

300 °C

200 bar

btc

PID temperature controller

for Type 3E and 4E vessels

Main reserch area was developing efficient, sustainable, and economic processes for waste chemicals upgrading into valuable hydrocarbons. Our Buchi midiclave reactor provides precise control over temperature, pressure, and residence time. Paired with its powerful cyclone stirrer, this reactor ensures thorough mixing of the viscous reactants, facilitating the controlled conversion of the carbon-rich feed into targeted products.

Additionally, the reactor is invaluable for numerous other batch reactions involving liquid and gaseous hydrocarbons such as hydro treatments. Its clear layout and easy-to-use fast action closure system make it an ideal tool for educational purposes, extending its utility beyond practical applications.

Empa Dübendorf, PD Dr. Andreas Borgschulte, Dr. Ali J. Saadun

Read the complete application note

Typical applications

- Hydrogenation reactor

- Hydrothermal reactions

- Hydrothermal reactor

- Polymerization reactor

- Synthesis reactor

- Catalyst testing / evaluation

- Catalytic reactor

- Chemical research

- Crystallization

- Corrosion measurement

- Hydrogen sulfide (H₂S) scavenger testing

- Petrochemical research

- Biomass research

- Biopolymer research

- Biorefinery research

- Biomass-to-liquids (BTL) research

- Biofuels research

- Thermal pressure hydrolysis (TPH)

- Corrosion testing autoclave

- Hydrogenation reactor

- Hydrothermal reactions

- Hydrothermal reactor

- Polymerization reactor

- Synthesis reactor

- Catalyst testing / evaluation

- Catalytic reactor

- Chemical research

- Crystallization

- Corrosion measurement

- Hydrogen sulfide (H₂S) scavenger testing

- Petrochemical research

- Biomass research

- Biopolymer research

- Biorefinery research

- Biomass-to-liquids (BTL) research

- Biofuels research

- Thermal pressure hydrolysis (TPH)

- Corrosion testing autoclave